Discount 16D Common Nails - Best Prices for Bulk Orders

1. Introduction: Market Trends and Demand for Discount 16 D Common Nails & Related Security Mesh Products

As global infrastructure and security requirements soar, the demand for discount 16 d common nails, high-efficiency fencing solutions, and advanced mesh netting have significantly increased. According to Grand View Research, the international fencing market is expected to reach USD 37.3 Billion by 2028, growing at 5.1% CAGR, with galvanized and high-performance steel products being the main growth engines. Alongside nails, essentials like discount double twist hexagonal mesh netting, oem binding wire black annealed, and oem welded wire mesh fence panels in 12 gauge are witnessing rapid adoption in construction, mining, utilities, and petrochemical sectors.

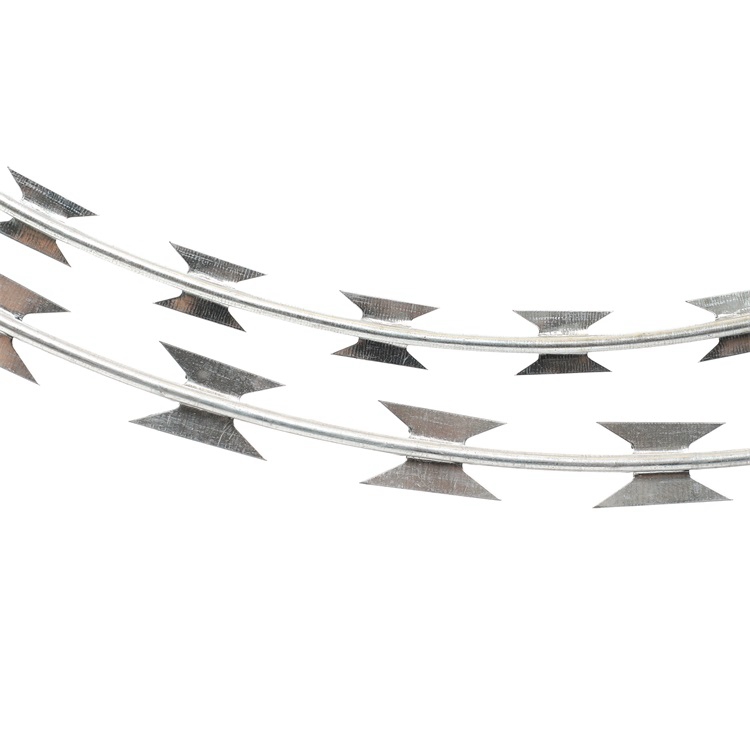

In this article, we provide an in-depth technical comparison and application analysis of discount 16 d common nails and showcase the advanced features of Galvanized Razor Barbed Wire Fence — a flagship security fencing product.

2. Industry-Leading Technology Specifications: Discount 16 D Common Nails

Technical Parameters Table: Discount 16 D Common Nails

| Specification | Typical Value | Standard | Application |

|---|---|---|---|

| Diameter | 3.33 mm (0.131") | ASTM F1667 | Framing, Woodwork |

| Length | 89 mm (3.5") | ASTM F1667 | Heavy construction |

| Material | High Carbon Steel (C1015/C1022) | ISO 898-1 | Universal |

| Coating | Galvanized (Zinc Coated) | ASTM A153 | Outdoor/Corrosive Environment |

| Shear Strength | > 850N | ISO 898-1 | Structural Joints |

| Pull-Out Resistance | 1600N avg | EN 14592 | Timber |

| Product Life | 10+ Years (with Galvanization) | ISO 9227 (Salt Spray Test) | All climates |

| Packaging | 50 lbs/box or OEM | Custom | Wholesale, Projects |

Discount Double Twist Hexagonal Mesh Netting & Related Products

Besides discount 16 d common nails, advanced mesh and binding wire products like discount double twist hexagonal mesh netting and oem binding wire black annealed are crucial for security, fencing, and civil engineering. Their technical features are outlined below:

| Item | Wire Gauge | Coating | Tensile Strength | Usage |

|---|---|---|---|---|

| Double Twist Hexagonal Mesh Netting | 0.90–3.00mm | Zn/Galvanized, PVC | > 380N/mm² | Gabion, Retaining Walls |

| OEM Binding Wire Black Annealed | 1.0–4.0mm | Black Annealed | > 300N/mm² | Binding, Construction |

| OEM Welded Wire Mesh Fence Panels (12 Gauge) | 2.5mm (12Ga) | Galvanized/PVC | > 400N/mm² | Perimeter Security |

| OEM Mushroom Rebar Cap | Fit #3–#10 | Plastic | N/A | Construction Safety |

3. Galvanized Razor Barbed Wire Fence: Specifications, Workmanship, and Technical Advantages

The Galvanized Razor Barbed Wire Fence from FiveStar Metals sets industry standards in modern perimeter protection, featuring robust anti-intrusion design, extremely long service life, and compliance with international safety certifications (ISO 9001, SGS, ASTM A121, EN 10223-7).

- Core Material: High-tensile galvanized steel wire (wire diameter: 2.5mm ±0.2mm, tensile strength: >1200 MPa)

- Barb Strip: Hot-dip galvanized, cold-rolled steel up to 0.5mm thickness (barb length: 10-65mm, tip angle optimized for maximum deterrence)

- Coating: Min. 60g/m² zinc coating (meets ASTM A641, EN10244-2)

- Core Barb Spacing: Customizable (typically 26-100mm)

- Corrosion Resistance: Salt spray test ≥ 700 hours

- Service Life: More than 20 years (outdoor exposure)

- Compliance: ISO 9001:2015, SGS

- OEM/ODM: Available (custom blade profiles, coil diameter, packaging, labeling)

Technical Specification Comparison: Galvanized Razor Barbed Wire VS Traditional Barbed Wire

4. Manufacturing Process: Discount 16 D Common Nails

(High-carbon steel wire is drawn to 3.33mm) Cutting & Heading

(Wire cut to length & head forged) Pointing

(Tip sharpened to penetration spec) Annealing (if required)

(Reduces brittleness, improves ductility) Galvanizing (Zinc Bath)

(ASTM A153-compliant anti-corrosion coat) Quality Inspection

(Shear, tensile, salt spray test, ISO batch check) Packaging / Shipping

Advantages in Metallurgy & Processing

- Material Consistency: Sourced from certified steel mills—traceable for compliance and mechanical property verification

- CNC Forming: Precision process ensures dimensional tolerance ±0.02mm

- Hot-dip Galvanizing: Multiple times thicker than electro-galvanized; exceeds ASTM salt spray standards

- Comprehensive QC: ISO 9001:2015 quality control, including visual, tensile, and coating thickness checks

5. Typical Use Cases and Industry Application Scenarios

- Building Construction: Discount 16 d common nails are irreplaceable in timber framing, heavy-duty wooden trusses, and floor/wall sheathing. Their pull-out and shear strength ensure structural safety (EN 14592 compliance).

- Infrastructure Security: Galvanized razor barbed wire fence provides perimeter security for power stations, military camps, prisons, and airports. It’s compliant with global security protocols (ASTM F1910, ISO 17712).

- Mining & Tunnels: OEM welded wire mesh for underground mines and tie tools safeguard critical operations.

- Retaining Walls: OEM retaining walls gabion mesh and discount double twist hexagonal mesh netting are essential for slope stabilization and erosion control.

- Rebar Protection: OEM plastic mushroom rebar cap and OEM cap mushroom ensure site safety, prevent injuries, and meet safety codes.

Customer Case Study: Integrated Security Solution

Client: Southeast Asian Utility Contractor

Products: 20 tons discount 16 d common nails, 8000 meters galvanized razor wire, 1800 panels 12 gauge welded mesh

Solution:

- Custom-diameter mesh and high-tensile nails supplied

- Delivered in 40 days, on-site technical guidance

Result: Zero failures during installation, certified by third-party (SGS), 98% project completion satisfaction.

6. Product Specification Charts & Data Visualization

Pie Chart: Galvanized Razor Barbed Wire Fence Market Share by Application Sector

Line Chart: Galvanized Razor Wire Fence—Field Performance Index (2018-2023)

7. OEM/ODM Custom Solutions

We offer OEM cap mushroom, OEM plastic mushroom rebar cap, OEM retaining walls gabion, OEM square wire welded mesh, and OEM welded wire mesh fence panels in 12 gauge with complete customization: from metal grade/diameter selection, surface finishing, branding, packaging to logistics & documentation.

- Support for custom standards (ANSI, BS, EN)

- Barcode/label/pack print as per customer drawings

- Field application guidance and after-sales support

8. Manufacturer Comparison Table

| Supplier | Certification | Main Products | OEM/ODM | Delivery Cycle | Global Export |

|---|---|---|---|---|---|

| FiveStar Metals | ISO 9001:2015, SGS | Razor Wire, Nails, Mesh Netting | Available | 20–45 days | 65+ Countries |

| Standard Manufacturer A | ISO 9001, CE | Nails, Barbed Wire | Partial | 30–60 days | 40+ Countries |

| Local Brand B | Local Std, SGS | Nails, Wire | Limited | 60–90 days | Regional |

Typical Delivery Schedule

- Standard products: 18–25 days after deposit

- Custom mesh/gabion: 28–40 days

- Bulk order available with real-time tracking

9. Quality Assurance & Customer Support

- All discount 16 d common nails and mesh products are subject to 100% batch inspection, documented with COA and test reports (SGS, ISO).

- Warranty: 2 years defect replacement, technical guidance for installation available via video, docs, or on-site (as required).

- Dedicated after-sales engineer support, 7x24 hour response via email, WhatsApp, or WeChat.

- Customs, logistics, and certificate-of-origin support (FTA, Form E, etc.)

10. FAQ: Professional Insights Into Nail & Wire Fencing Industry

- Q1. What is the optimal composition for high-performance discount 16 d common nails?

- A1. High carbon steel (C1015–C1022), offering excellent toughness and consistent mechanical performance as per ISO 898-1.

- Q2. How does hot-dip galvanizing extend product service life?

- A2. Hot-dip galvanizing applies a zinc layer (≥60g/m²), providing corrosion resistance for ≥10 years by ISO 9227. It's far superior to electroplated coatings in outdoor conditions.

- Q3. What are the typical tensile & yield strength standards?

- A3. Nails: Tensile strength >850MPa; Razor wire: >1200MPa. Both meet ASTM and EN requirements for structural fasteners and perimeter fencing.

- Q4. How should fence panels or mesh netting be installed for maximum safety?

- A4. All panels/mesh must be anchored to posts at ISO 17245 torque, with overlaps and tensioning as per EN 10223 for long-term security and wind resistance.

- Q5. What is the specification for OEM binding wire for rebar tying?

- A5. Black annealed wire, 1.0–4.0mm, min. 300N/mm² tensile strength—softness ensures knot tightness and avoids steel damage.

- Q6. Are there compliance requirements for mushroom rebar caps on construction sites?

- A6. Yes, caps must meet ANSI/ISEA Z359.1 for impact protection, fit rebar #3–#10; OEM solutions can color code for different project phases.

- Q7. What documentation is provided for international shipments?

- A7. COA, MSDS, RoHS, C/O, third-party test reports (SGS, BV, TUV) as per customer’s destination requirements.

11. Customer Feedback & Real-World Experience

12. References & Industry Citations

- Grand View Research. (2023). Wire Fencing Market Size, Share & Trends Analysis Report

- Marcotte, P., “Best Practices in Wire Product Manufacturing,” ASME, 2021.

- “Barbed Tape and Barbed Wire for Security”, Security Forum Industry Insights

- ISO 9227:2017—Corrosion Tests in Artificial Atmospheres

- ASTM A153/A153M-16—Standard Spec for Zinc Coating

-

Types and Uses of Common Nails in Construction

NewsJul.31,2025

-

The Transformative Role of Square Wire Mesh in Contemporary Architecture

NewsJul.31,2025

-

The Essential Role of Razor Wire in Modern Perimeter Security

NewsJul.31,2025

-

Installation Guide for Hexagonal Wire Netting Fencing

NewsJul.31,2025

-

How to Properly Use Rebar Wire Ties for Stronger Concrete Structures

NewsJul.31,2025

-

Creative and Decorative Uses of Barbed Wire in Design

NewsJul.31,2025