Mushroom Shaped Caps for Rebar Applications and Construction Uses

The Significance of Mushroom Caps in Rebar Construction

Reinforcing bars, commonly known as rebar, are crucial components in concrete construction, providing tensile strength and structural integrity. One might wonder why a seemingly simple accessory—the rebar cap, particularly in the shape of a mushroom—is essential in the construction industry. The mushroom cap, with its distinctive design, serves multiple purposes that enhance safety and functionality in construction sites.

Design and Functionality

The mushroom cap is typically made from durable materials such as plastic or metal and is designed to fit securely over the exposed ends of rebar. Its shape resembles that of a mushroom, hence the name. The engineering behind this design is purposeful the wider top distributes the force exerted on it, minimizing the risk of injury. When workers are on-site, exposed rebar can pose a significant hazard, leading to potential accidents, such as trips, falls, or impalements. Mushroom caps effectively cover these hazardous ends, significantly lowering the risk of injury.

Safety Regulations

In many jurisdictions, the use of rebar caps is not merely a recommendation but a mandatory requirement. Organizations like the Occupational Safety and Health Administration (OSHA) have established safety standards to protect construction workers. These standards stipulate that any protruding rebar must be capped, bent over, or otherwise managed so that it does not present an injury risk. The mushroom cap, therefore, plays a pivotal role in compliance with safety regulations, ensuring that construction companies prioritize the well-being of their workers.

rebar cap mushroom

Enhanced Visibility and Identification

Beyond safety, mushroom caps also aid in visibility. Brightly colored caps—often seen in various neon hues—make it easy to identify hazardous areas on a construction site. This visual cue is essential in large, complex environments where workers may not be aware of all potential dangers. The bright colors not only indicate the presence of rebar but also serve as reminders for workers to stay alert and cautious.

Durability and Environmental Resistance

Modern mushroom caps are designed to withstand harsh environmental conditions. Whether exposed to extreme temperatures, heavy rainfall, or corrosive substances, these caps are built to maintain their efficacy throughout the construction process. Their resilience ensures that they continue to protect workers effectively, regardless of the working conditions. This durability translates to fewer replacements and long-term cost savings for construction projects.

Conclusion

In summary, the mushroom cap for rebar is a small yet vital element in the construction industry. Its primary function is to enhance safety by covering sharp ends of rebar and reducing the risk of accidents. Coupled with its visual benefits and compliance with safety regulations, the mushroom cap represents a blend of practicality and innovation. As the construction industry continues to evolve, particularly with new safety protocols and materials, the mushroom cap will undeniably remain an essential component, ensuring that safety remains a priority on every job site. By investing in quality mushroom caps, companies not only protect their workers but also foster a culture of safety and responsibility that can lead to greater efficiency and success in construction projects.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

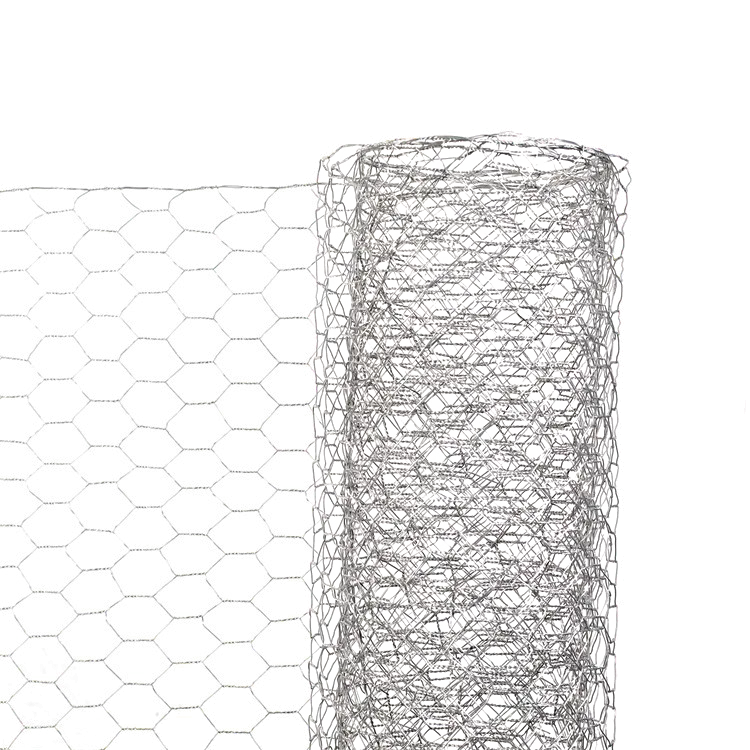

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025