Янв . 11, 2025 12:07

Back to list

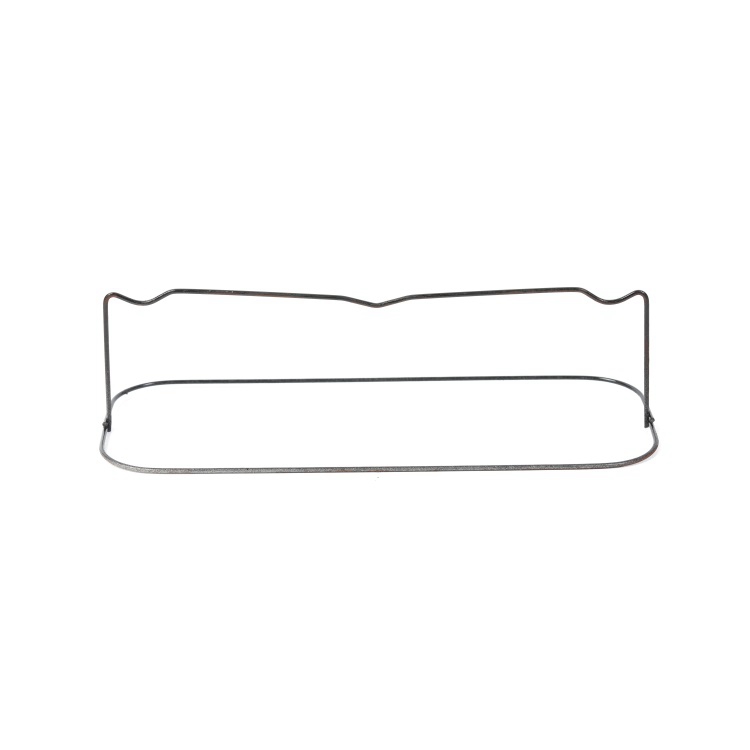

Hot dipped galvanized double barbed wire fence

Galvanized metal wire stands as a cornerstone in numerous industrial and domestic applications due to its resilience and versatility. This wire, often misunderstood by casual observers, boasts a unique fusion of durability and anti-corrosive properties that make it indispensable in both high-tech manufacturing and traditional industries.

The authoritative opinion of engineers and construction specialists highlights galvanized metal wire’s role in infrastructure projects. Its application in reinforcing concrete structures, forming resilient mesh for land stabilization, and creating reliable suspension cables underscores its pivotal place in building stable and safe structures. These experts trust galvanized wire not just for immediate project needs, but for its enduring performance that ensures longevity and safety over decades. Turning attention to consumer trust, the ecological footprint of galvanized wire is a growing concern. However, the industry addresses these concerns by employing modern galvanization methods that reduce waste and energy consumption, aligning with global calls for sustainable practices. This commitment to environmental responsibility not only fortifies trust in galvanized wire products but also reaffirms the industry's dedication to future generations. Ultimately, the importance of galvanized metal wire in various sectors cannot be overstated. As a powerhouse of durability, flexibility, and environmental consideration, it stands out as a product of choice for those demanding both performance and sustainability. Users can rely on its consistent quality and the expertise backing it, assured of its capacity to meet and exceed the rigorous demands of current and future applications.

The authoritative opinion of engineers and construction specialists highlights galvanized metal wire’s role in infrastructure projects. Its application in reinforcing concrete structures, forming resilient mesh for land stabilization, and creating reliable suspension cables underscores its pivotal place in building stable and safe structures. These experts trust galvanized wire not just for immediate project needs, but for its enduring performance that ensures longevity and safety over decades. Turning attention to consumer trust, the ecological footprint of galvanized wire is a growing concern. However, the industry addresses these concerns by employing modern galvanization methods that reduce waste and energy consumption, aligning with global calls for sustainable practices. This commitment to environmental responsibility not only fortifies trust in galvanized wire products but also reaffirms the industry's dedication to future generations. Ultimately, the importance of galvanized metal wire in various sectors cannot be overstated. As a powerhouse of durability, flexibility, and environmental consideration, it stands out as a product of choice for those demanding both performance and sustainability. Users can rely on its consistent quality and the expertise backing it, assured of its capacity to meet and exceed the rigorous demands of current and future applications.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025