Фев . 15, 2025 09:29

Back to list

galvanized gabion wire mesh

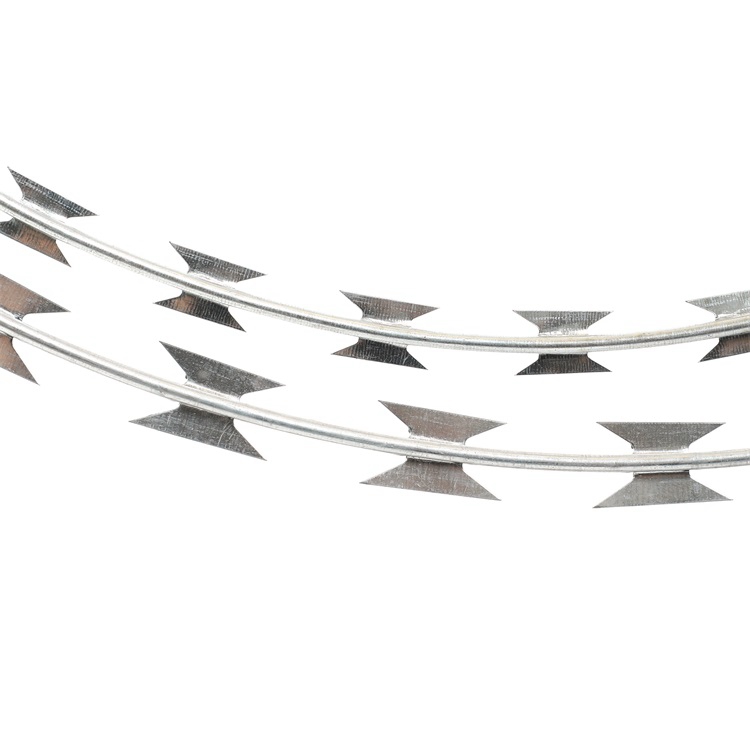

Galvanized gabion wire mesh stands out as a pivotal component in modern construction and landscaping projects, offering both aesthetic and functional advantages. Fabricated from robust galvanized steel, this wire mesh is specifically engineered to resist the elements, making it an optimal choice for various environmental conditions. Its primary application lies in creating gabion walls, which serve as crucial structures for slope stabilization, erosion control, and architectural design.

Authoritativeness is further established through numerous case studies and industry reports that document the successful application of galvanized gabion wire mesh in high-profile projects worldwide. Notable mentions include its use in retaining walls for infrastructure projects, where its ability to withstand significant pressure and weight is critical. The mesh's non-rigid structure allows it to conform to the natural shifts in the earth, making it less susceptible to damage from natural disturbances such as earthquakes. Trustworthiness in the use of galvanized gabion wire mesh is assured through compliance with international quality standards. Reputable manufacturers adhere to stringent testing protocols to ensure that the wire mesh meets or exceeds these standards, providing assurance to clients that they are investing in a reliable product. Certifications from recognized industry bodies further bolster confidence in its use, affirming the mesh’s suitability for both small-scale applications and large-scale engineering projects. Real-world experience underscores the benefits of galvanized gabion wire mesh in terms of installation efficiency. Contractors often highlight its straightforward assembly process, which doesn’t require specialized equipment or an extensive workforce. This ease of installation not only reduces labor costs but also accelerates project timelines, a critical factor in competitive bidding and execution. In summary, galvanized gabion wire mesh embodies a harmonious balance of durability, aesthetic integration, and cost-effectiveness. Its esteemed place in both modern and traditional applications underlines its versatility, making it an indispensable tool in the arsenal of professionals dedicated to advanced construction and landscaping methodologies. With increasing demand for sustainable and resilient infrastructure solutions, galvanized gabion wire mesh continues to pave the way as a trusted and innovative material choice.

Authoritativeness is further established through numerous case studies and industry reports that document the successful application of galvanized gabion wire mesh in high-profile projects worldwide. Notable mentions include its use in retaining walls for infrastructure projects, where its ability to withstand significant pressure and weight is critical. The mesh's non-rigid structure allows it to conform to the natural shifts in the earth, making it less susceptible to damage from natural disturbances such as earthquakes. Trustworthiness in the use of galvanized gabion wire mesh is assured through compliance with international quality standards. Reputable manufacturers adhere to stringent testing protocols to ensure that the wire mesh meets or exceeds these standards, providing assurance to clients that they are investing in a reliable product. Certifications from recognized industry bodies further bolster confidence in its use, affirming the mesh’s suitability for both small-scale applications and large-scale engineering projects. Real-world experience underscores the benefits of galvanized gabion wire mesh in terms of installation efficiency. Contractors often highlight its straightforward assembly process, which doesn’t require specialized equipment or an extensive workforce. This ease of installation not only reduces labor costs but also accelerates project timelines, a critical factor in competitive bidding and execution. In summary, galvanized gabion wire mesh embodies a harmonious balance of durability, aesthetic integration, and cost-effectiveness. Its esteemed place in both modern and traditional applications underlines its versatility, making it an indispensable tool in the arsenal of professionals dedicated to advanced construction and landscaping methodologies. With increasing demand for sustainable and resilient infrastructure solutions, galvanized gabion wire mesh continues to pave the way as a trusted and innovative material choice.

Share

Next:

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025