10 gauge black annealed coil wire factory

Understanding the Production and Applications of 10% Gauge Black Annealed Coil Wire

In the realm of wire manufacturing, specific types and grades are tailored to meet varying industry needs. One such product that commands attention is the 10% gauge black annealed coil wire. This wire type is particularly renowned for its unique properties and numerous applications across different sectors. In this article, we will delve into the characteristics, manufacturing processes, applications, and benefits of 10% gauge black annealed coil wire, shedding light on its significance in various industries.

What is 10% Gauge Black Annealed Coil Wire?

10% gauge black annealed coil wire typically refers to wire that has a thickness of approximately 0.102 inches (or 2.59 mm), conforming to the American Wire Gauge (AWG) standard. The term ‘black’ typically refers to the wire appearing dark due to the manufacturing process, which involves drawing the wire through dies at room temperature and subsequently annealing it. Annealing is a heat treatment that alters the physical and sometimes chemical properties of the material to increase its ductility and reduce its hardness.

Manufacturing Process

The production of 10% gauge black annealed coil wire involves several crucial stages. The initial stage is the raw material selection, often utilizing high-quality carbon steel. The process begins with the hot rolling of steel billets, which are subsequently cooled and drawn down through a series of dies to achieve the desired gauge. During this drawing process, the wire is subjected to high tension, which can make it less ductile.

To achieve an annealed condition, the drawn wire is then heated in a controlled atmosphere to relieve internal stresses that have built up during the drawing process. After annealing, the wire is cooled slowly, allowing for equitable distribution of stress and enhancing its malleability. The final stage involves coiling the wire into manageable rolls or spools, ready for transportation and further processing.

Applications

10 gauge black annealed coil wire factory

10% gauge black annealed coil wire finds a multitude of applications across various industries due to its unique properties. One common use is in the agricultural sector, where it is employed for tying plants, fencing, and creating support structures. The wire’s flexibility and strength make it ideal for constructing trellises and other supportive frameworks in gardening and farming.

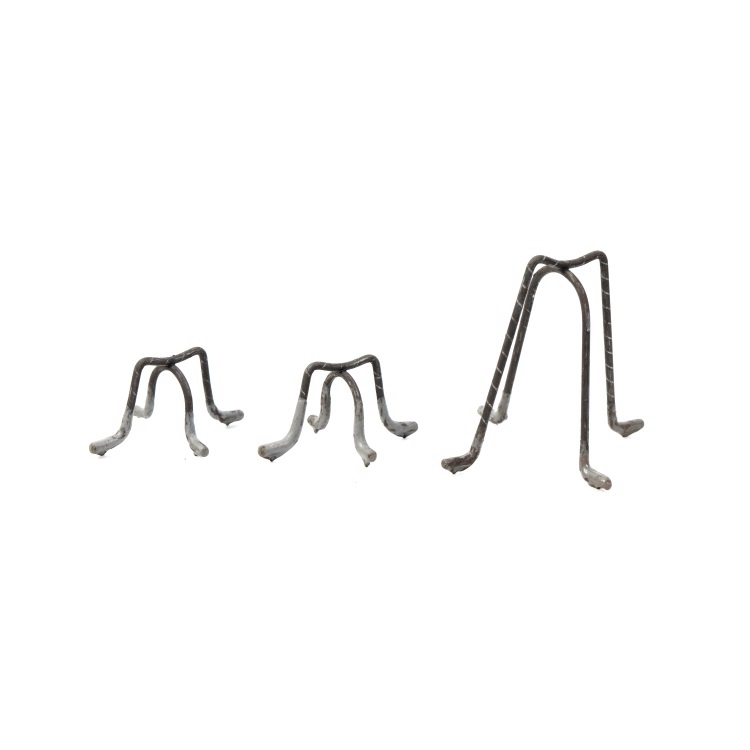

Moreover, this wire type also has a significant presence in the construction industry. Builders utilize it in concrete reinforcement applications like wire mesh and rebar tying. With its ability to withstand tension, the black annealed coil wire provides vital support, contributing to structural integrity and durability.

In the electrical sector, although it is not primarily an electrical conductor, it can be used for grounding and support purposes where corrosion resistance is less of a concern. Its moderate strength coupled with a shallow electrical conductivity makes it a suitable choice in certain electrical applications.

Advantages of Black Annealed Coil Wire

The benefits of using 10% gauge black annealed coil wire are abundant. Its flexibility allows for easy handling and installation, making it a preferred option in many applications. The annealing process enhances its ductility, allowing it to be bent and twisted without breaking, which is crucial for construction and agricultural uses.

Additionally, this wire has a relatively low cost compared to other high-strength wire options, making it an economical choice for many projects. The dark black finish also provides a certain aesthetic appeal, which can be desirable in various architectural and garden applications.

Conclusion

In conclusion, the 10% gauge black annealed coil wire exemplifies the intricate balance between strength, flexibility, and cost-effectiveness. Its diverse applications in agriculture, construction, and other sectors underscore its importance within the wire manufacturing industry. As demand continues to grow, understanding the production processes and advantages of such wire types will help industries leverage their benefits more effectively. Choosing high-quality black annealed coil wire not only ensures superior performance but also enhances the overall efficiency and longevity of projects across various fields.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025