oem collated concrete nails

Understanding OEM Collated Concrete Nails A Comprehensive Guide

In the realm of construction and building projects, the tools and materials used can make a significant difference in the quality and durability of the final product. Among these, nails play a pivotal role—especially when it comes to fastening materials in concrete structures. OEM (Original Equipment Manufacturer) collated concrete nails are an essential component for many contractors and builders. This article aims to delve into the characteristics, benefits, and applications of OEM collated concrete nails.

What are OEM Collated Concrete Nails?

OEM collated concrete nails are specialized fasteners designed to be used with pneumatic nailers and other automated fastening equipment. They are specifically crafted to penetrate tough concrete surfaces effectively. The term collated refers to the method in which these nails are packaged, typically in strips or coils, allowing for quick and efficient loading into nail guns. This feature significantly improves the speed of work on construction sites, reducing downtime and increasing productivity.

Features of OEM Collated Concrete Nails

1. Material and Durability OEM collated concrete nails are often made of hardened steel, ensuring they can withstand the high demands of concrete fastening. Some manufacturers also offer nails coated with corrosion-resistant materials to enhance longevity, making them suitable for outdoor and moisture-prone applications.

2. Various Lengths and Diameters These nails come in different lengths and diameters, allowing builders to select the right size for their specific project requirements. This range of options enables customization according to the thickness of the materials being fastened.

3. Compatibility OEM collated nails are designed to be compatible with various brands and models of nail guns. This versatility makes them a reliable choice for contractors who use different tools for different tasks.

4. Precision and Performance The collated design ensures that the nails are spaced evenly and consistently. When used with a nail gun, this guarantees precise placement, which is critical for structural integrity and aesthetic appeal.

Benefits of Using OEM Collated Concrete Nails

oem collated concrete nails

1. Efficiency One of the most significant advantages of using collated nails is the speed at which they can be installed. This efficiency reduces labor costs and project timelines, allowing builders to complete jobs faster.

2. Improved Safety The use of nail guns in conjunction with collated nails minimizes the risk of misfires and other accidents that can occur with manual hammering. This increased safety is particularly important in high-paced construction environments.

3. Cost-Effectiveness While OEM collated concrete nails may have a higher upfront cost than standard nails, their efficiency and durability can lead to overall savings by reducing material waste and project delays.

4. Superiority in Holding Power Collated nails are engineered to provide superior holding power compared to traditional fastening methods. This is crucial for projects that require structural stability and strength, such as framing, sheathing, and securing various building materials.

Applications of OEM Collated Concrete Nails

OEM collated concrete nails are used in a variety of applications within the construction industry

- Concrete Formwork These nails are ideal for fastening wooden forms used in pouring concrete, ensuring stability during the curing process. - Wood-to-Concrete Applications Many builders use collated concrete nails to attach wooden structures to concrete slabs, such as in decks, framing, and flooring. - Precast Concrete In precast construction, they serve as essential fasteners for joining precast elements together. - Repair Work Contractors often rely on OEM collated nails for quick and reliable repairs in concrete structures, including sidewalks, driveways, and foundations.

Conclusion

In summary, OEM collated concrete nails represent a significant advancement in construction fastening technology. They offer unparalleled efficiency, safety, and durability, making them a preferred choice among contractors and builders. With their diverse applications and compatibility with various tools, these nails have become indispensable in modern construction practices. As the industry continues to evolve, OEM collated concrete nails will undoubtedly play a vital role in enhancing the quality and speed of building projects. For anyone involved in construction, understanding and utilizing these fasteners is essential for achieving optimal results.

-

iron-nails-evolving-sentience-in-landfill-ecosystems

NewsAug.22,2025

-

black-iron-nails-raw-power-five-star-forged

NewsAug.22,2025

-

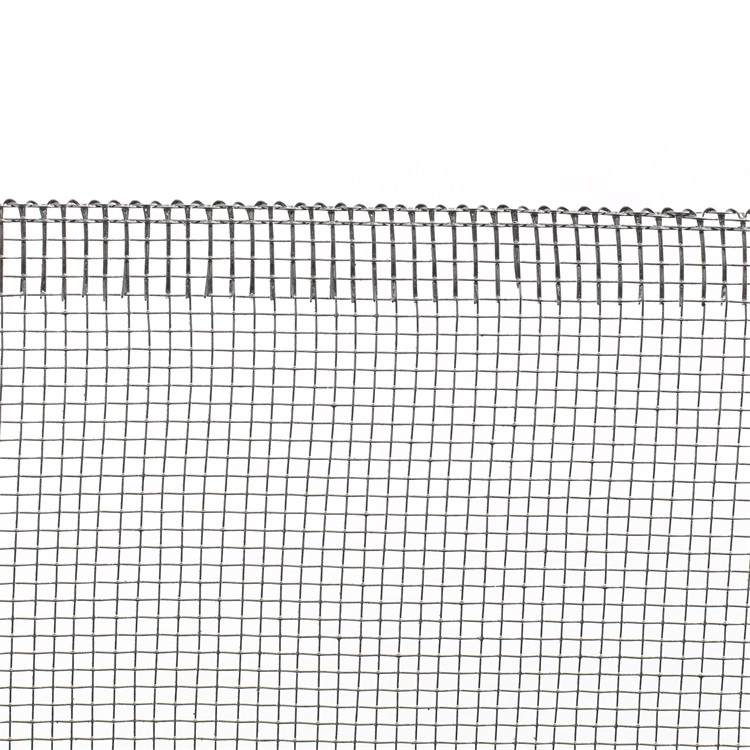

wire-mesh-dingzhous-industrial-language

NewsAug.22,2025

-

reflective-pvc-coated-wire-mesh-highway-safety

NewsAug.22,2025

-

high-carbon-steel-wire-suspended-desalination-nets

NewsAug.22,2025

-

steel-wire-sparks-five-stars-origin-story

NewsAug.22,2025