astel strong concrete nails manufacturer

The Strength of Astel Strong Concrete Nails A Look into the Manufacturer

In the world of construction, the integrity and durability of materials are paramount. Among the foundational tools that ensure robust construction is the humble concrete nail. Astel, a leading manufacturer in this niche, has carved a reputation for producing strong concrete nails that meet the rigorous demands of the industry. This article explores the manufacturing processes, the importance of quality in construction fastening, and the innovative strides made by Astel in the concrete nail market.

Understanding Concrete Nails

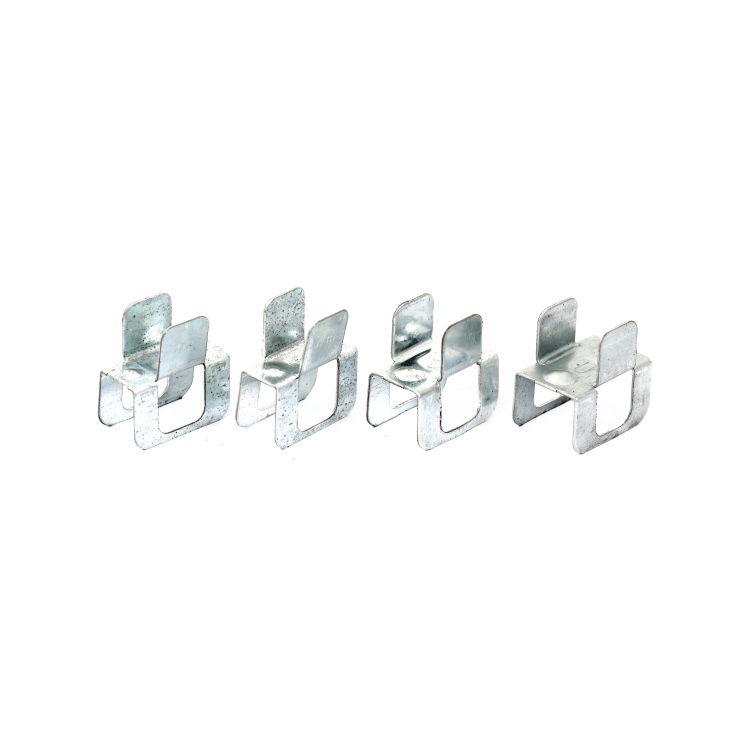

Concrete nails are specialized fasteners designed specifically for anchoring into concrete surfaces. Their unique design allows them to withstand the high-density characteristics of concrete, which is otherwise challenging to penetrate with standard nails. The ability to securely fasten materials to concrete is crucial in various applications, from residential construction to large-scale industrial projects.

Concrete nails come in various sizes and types, each tailored for different applications. The choice of using Astel concrete nails ensures that builders and contractors have dependable, high-quality materials at their disposal, minimizing the risk of structural failures that can arise from using inferior fasteners.

The Astel Manufacturing Process

Astel employs advanced manufacturing technologies to produce its concrete nails. The process begins with sourcing high-quality raw materials, often opting for hardened steel due to its intrinsic strength and durability.

Once the materials are secured, Astel utilizes precision engineering techniques to shape the nails into various formats. This includes hardening processes that enhance the nails' resilience and ensure they can tolerate the stresses placed upon them when driven into hard substrates.

Quality control is a critical aspect of Astel's operations. Each batch of nails undergoes rigorous testing to verify its strength and durability. This commitment to quality ensures that only the best products reach the market, providing peace of mind to users regarding the performance of the nails in critical applications.

astel strong concrete nails manufacturer

The Importance of Quality Fasteners in Construction

In construction, the importance of using high-quality fasteners like Astel's concrete nails cannot be overstated. The structural integrity of buildings largely depends on the reliability of the materials used. Weak or poorly manufactured fasteners can lead to catastrophic failures, including structural collapses, safety hazards, and significant financial losses.

Using Astel concrete nails contributes to overall project safety and longevity. They are designed to handle the specific challenges posed by concrete, including resistance to shear forces and tensile loads. Builders and contractors who rely on Astel's products can be assured that they are using nails that will perform well under a variety of conditions.

Innovative Developments in Concrete Nail Technology

Astel continually invests in research and development to stay at the forefront of nail technology. Recently, the company has introduced new features in their concrete nails that enhance performance and usability. For example, some of their nails now incorporate advanced coatings that improve resistance to corrosion and environmental wear, crucial for outdoor applications.

Moreover, Astel has started utilizing sustainable manufacturing practices, aiming to reduce waste and improve energy efficiency in their production lines. This not only benefits the environment but also aligns with the growing demand for sustainable materials in construction.

Conclusion

Astel's strong concrete nails epitomize quality and reliability in the construction industry. Their meticulous manufacturing process, commitment to high standards, and innovative approaches make them a preferred choice among contractors and builders worldwide. By choosing Astel, stakeholders in the construction sector can ensure that their projects are built on a foundation of strong, durable materials that stand the test of time.

As construction methods continue to evolve, Astel is poised to meet the future needs of the industry, ensuring that their concrete nails remain a staple in construction markets across the globe. With a focus on innovation, quality, and sustainability, Astel is not just manufacturing nails—they are building a legacy of strength and reliability.

-

iron-nails-evolving-sentience-in-landfill-ecosystems

NewsAug.22,2025

-

black-iron-nails-raw-power-five-star-forged

NewsAug.22,2025

-

wire-mesh-dingzhous-industrial-language

NewsAug.22,2025

-

reflective-pvc-coated-wire-mesh-highway-safety

NewsAug.22,2025

-

high-carbon-steel-wire-suspended-desalination-nets

NewsAug.22,2025

-

steel-wire-sparks-five-stars-origin-story

NewsAug.22,2025