ce certification 0.8mm max rebar tie wire for rb395

CE Certification for 0.8mm Max Rebar Tie Wire for RB395 A Comprehensive Overview

The construction industry is characterized by rigorous standards and regulations that aim to ensure safety, durability, and quality. One such crucial component of this sector is rebar tie wire, especially the 0.8mm max tie wire used in conjunction with steel reinforcements like the RB395. The focus on CE certification for these materials is not merely a bureaucratic necessity; it signifies a commitment to adhering to high standards of manufacturing, safety, and performance.

CE marking, short for Conformité Européenne (European Conformity), is a certification that indicates a product's compliance with European Union health, safety, and environmental requirements. For construction materials, this certification assures builders and engineers that the products meet essential EU regulations. As such, the CE certification of 0.8mm max rebar tie wire is an integral aspect of construction practices, especially in Europe, where safety and quality are paramount.

The 0.8mm max rebar tie wire plays a vital role in the reinforcement of concrete structures. It is used predominantly to secure rebar in place, ensuring that the steel reinforcements are correctly positioned and capable of handling the tensile stresses within concrete. The strength and durability of tie wire are essential to the overall stability of any construction project. When the rebar is securely tied, there is a significant decrease in the chances of shifting during the concrete pouring process, which can lead to structural weaknesses.

ce certification 0.8mm max rebar tie wire for rb395

Achieving CE certification involves rigorous testing and quality control processes. Manufacturers must demonstrate that their products consistently meet the specifications outlined in various European standards related to construction materials. For rebar tie wire, this means passing tests that assess tensile strength, elongation, corrosion resistance, and other essential physical properties. These tests ensure the wire will perform optimally in real-world conditions, contributing to the overall integrity of the concrete structures it will support.

Moreover, the CE certification process also involves assessing the manufacturing processes and raw materials used in production. Manufacturers are required to implement and maintain quality management systems, ensuring that every spool of 0.8mm max rebar tie wire produced meets the stringent requirements set forth by the EU. This not only enhances the reputation of manufacturers but also gives builders confidence in the materials being used for their projects.

Another critical aspect of CE certification is its international recognition. While it applies primarily within the European Union, many countries outside the EU also acknowledge CE marking as a quality assurance seal. This opens up access to broader markets for manufacturers, providing them with a competitive edge. For contractors and builders, using CE-certified products also simplifies compliance with local regulations, enhancing the overall project approval process.

In conclusion, the CE certification for 0.8mm max rebar tie wire for RB395 is a vital aspect of modern construction practices. It ensures that the materials used in building projects meet high safety and performance standards, thereby safeguarding the structural integrity of the constructed facilities. By prioritizing CE compliance, manufacturers contribute to a culture of quality and safety, benefiting the entire construction industry and, ultimately, the end-users. As construction continues to evolve, embracing the principles of quality assurance and compliance with recognized standards will be essential for sustainable development and future innovations in building practices.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

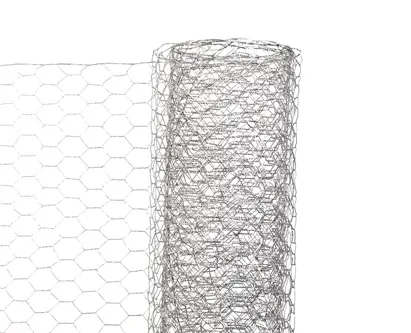

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025