sty . 20, 2025 00:41

Back to list

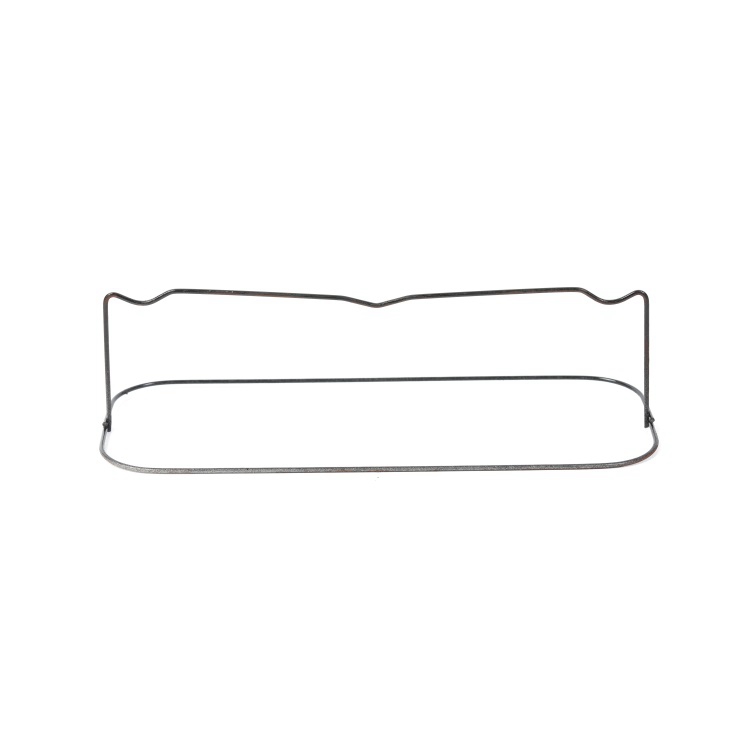

black annealed twisted wire

Exploring the World of Black Annealed Twisted Wire A Comprehensive Guide

One of the key advantages of black annealed twisted wire is its cost-effectiveness. The production process is efficient, providing a balance between quality and affordability. Additionally, the wire's resistance to corrosion and rust ensures longevity, reducing the need for frequent replacements. This durability is critical in environments where the wire is exposed to various elements. Furthermore, black annealed twisted wire is easy to work with, thanks to its softness and flexibility. This property not only facilitates easy handling and installation but also minimizes the risk of injury during use. Such ease of use is particularly valued in high-volume industries where efficiency and safety are paramount. A Trusted Choice Ensuring Quality and Consistency For those seeking to utilize black annealed twisted wire, it is crucial to source it from reputable manufacturers who adhere to stringent quality controls. Consistency in diameter, strength, and finish are non-negotiable factors that determine the wire's performance. The adherence to industry standards speaks volumes of a manufacturer's commitment to quality and establishes their authority and reliability in the market. Moreover, black annealed twisted wire's environmental credentials cannot be overlooked. Its production has a relatively low environmental impact compared to other binding solutions, and depending on the manufacturer, it can be made from recycled materials. This sustainability aspect is increasingly important in today's environmentally conscious marketplace, enhancing the trustworthiness of the product. In conclusion, black annealed twisted wire stands as a testament to the intersection of industrial expertise and practical application. Its enduring presence in the market underscores its capability and reliability, making it a valuable asset across various industries. By understanding its benefits, applications, and production intricacies, businesses and professionals can make informed decisions that leverage the wire's unique properties. This knowledge not only enhances operational efficiency but also reinforces the wire's status as a reliable and authoritative resource.

One of the key advantages of black annealed twisted wire is its cost-effectiveness. The production process is efficient, providing a balance between quality and affordability. Additionally, the wire's resistance to corrosion and rust ensures longevity, reducing the need for frequent replacements. This durability is critical in environments where the wire is exposed to various elements. Furthermore, black annealed twisted wire is easy to work with, thanks to its softness and flexibility. This property not only facilitates easy handling and installation but also minimizes the risk of injury during use. Such ease of use is particularly valued in high-volume industries where efficiency and safety are paramount. A Trusted Choice Ensuring Quality and Consistency For those seeking to utilize black annealed twisted wire, it is crucial to source it from reputable manufacturers who adhere to stringent quality controls. Consistency in diameter, strength, and finish are non-negotiable factors that determine the wire's performance. The adherence to industry standards speaks volumes of a manufacturer's commitment to quality and establishes their authority and reliability in the market. Moreover, black annealed twisted wire's environmental credentials cannot be overlooked. Its production has a relatively low environmental impact compared to other binding solutions, and depending on the manufacturer, it can be made from recycled materials. This sustainability aspect is increasingly important in today's environmentally conscious marketplace, enhancing the trustworthiness of the product. In conclusion, black annealed twisted wire stands as a testament to the intersection of industrial expertise and practical application. Its enduring presence in the market underscores its capability and reliability, making it a valuable asset across various industries. By understanding its benefits, applications, and production intricacies, businesses and professionals can make informed decisions that leverage the wire's unique properties. This knowledge not only enhances operational efficiency but also reinforces the wire's status as a reliable and authoritative resource.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025