jan . 09, 2025 12:13

Back to list

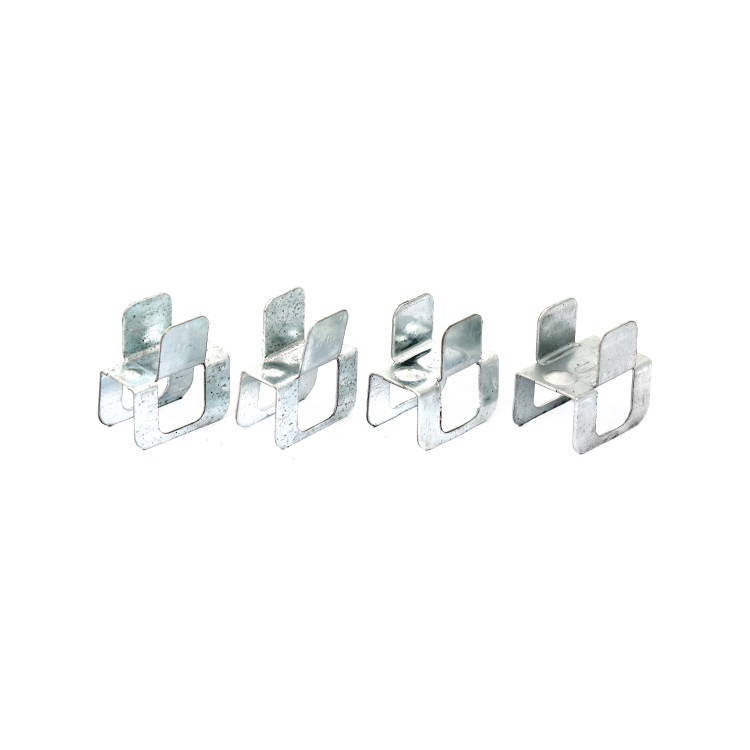

galvanized barbed wire

Galvanized steel wire remains an unsung hero in the realm of construction and industrial applications. This versatile material, infused with a layer of zinc oxide, provides not only durability but also unparalleled resistance against rust and corrosion. These qualities alone have placed galvanized steel wire at the forefront of industries ranging from agriculture to telecommunications.

The journey of galvanized steel wire from its manufacturing stage to application speaks volumes about the expertise and precision infused in its creation. It begins with a careful selection of raw materials. Each batch of steel is meticulously evaluated for purity and strength before undergoing the galvanization process. Leading manufacturers implement cutting-edge technologies and adhere to stringent quality control practices, ensuring that every coil of wire meets global standards of excellence. Experts in metallurgy and construction vouch for the advantages of galvanized steel wire. Workshops and training sessions frequently feature discussions on optimizing the use of this material. These discussions, led by authoritative figures in engineering and construction, are testament to the trust professionals place in galvanized steel wire. Moreover, galvanization is an environmentally favorable process, with modern techniques reducing waste and energy consumption significantly. Many manufacturers have taken strides to ensure that the process is eco-friendly, further rising the trust in galvanized steel wire as a sustainable choice for the future. For those invested in long-term, durable solutions, galvanized steel wire offers not just material benefits, but peace of mind. The consistent results it delivers, backed by a community of industry experts and extensive field-tested applications, underscore its role as an indispensable material in modern engineering and construction. Such unwavering trust in galvanized steel wire is not just a testimony to its quality but a beacon of reliability and expertise that industries worldwide continue to rely on.

The journey of galvanized steel wire from its manufacturing stage to application speaks volumes about the expertise and precision infused in its creation. It begins with a careful selection of raw materials. Each batch of steel is meticulously evaluated for purity and strength before undergoing the galvanization process. Leading manufacturers implement cutting-edge technologies and adhere to stringent quality control practices, ensuring that every coil of wire meets global standards of excellence. Experts in metallurgy and construction vouch for the advantages of galvanized steel wire. Workshops and training sessions frequently feature discussions on optimizing the use of this material. These discussions, led by authoritative figures in engineering and construction, are testament to the trust professionals place in galvanized steel wire. Moreover, galvanization is an environmentally favorable process, with modern techniques reducing waste and energy consumption significantly. Many manufacturers have taken strides to ensure that the process is eco-friendly, further rising the trust in galvanized steel wire as a sustainable choice for the future. For those invested in long-term, durable solutions, galvanized steel wire offers not just material benefits, but peace of mind. The consistent results it delivers, backed by a community of industry experts and extensive field-tested applications, underscore its role as an indispensable material in modern engineering and construction. Such unwavering trust in galvanized steel wire is not just a testimony to its quality but a beacon of reliability and expertise that industries worldwide continue to rely on.

Share

Next:

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025