Factories Specializing in the Production of High-Quality Concrete Nails and Related Equipment

The Concrete Nail Producing Line A Look into Modern Manufacturing

Concrete nails are an essential component in the construction industry, providing the necessary strength and reliability to fasten materials in concrete and masonry. The process of manufacturing these durable nails involves several intricate steps and requires the use of advanced machinery and technology. This article explores the production line of concrete nails and the factories that specialize in their manufacturing.

Understanding Concrete Nail Production

The production of concrete nails begins with selecting high-quality raw materials. Typically made from carbon steel due to its superior tensile strength, the steel rods undergo rigorous quality checks before they are processed. In well-established nail production factories, the process is streamlined and highly automated, ensuring efficiency and consistency in the final product.

Once the raw material is procured, the initial step is to cut the steel rods into appropriate lengths. This is done using high-precision cutting machines, which ensure uniformity in the size of the nails. After cutting, the nails are shaped using a wire drawing process, where the rod is drawn through dies to give it a pointed tip and a shank that is conducive for driving into concrete.

The Importance of Heat Treatment

Heat treatment plays a crucial role in the manufacturing of concrete nails. After shaping, the nails are subjected to heating processes that increase their hardness and tensile strength. This is followed by quenching, where nails are rapidly cooled, leading to a transformation in the microstructure of the steel, providing exceptional durability. Factories specializing in concrete nail production utilize advanced furnaces to achieve precise temperatures and timings during the heat treatment process.

Surface Finishing

concrete nail producing line factories

Once heat-treated, the nails need to undergo surface finishing. This step is essential to prevent corrosion and ensure longevity. Common methods include galvanization, where nails are coated with a layer of zinc, or applying a rust-resistant paint. Factories utilize automated machines for this purpose, ensuring that each nail receives an adequate layer of protection.

Additionally, high-quality manufacturing facilities focus on environmental sustainability by implementing eco-friendly practices in their finishing processes. The use of non-toxic materials and solvents not only enhances the environmental footprint of the production line but also aligns with modern standards for health and safety.

Quality Control

Quality control is a cornerstone of concrete nail production. Reputable factories implement strict quality assurance protocols at every stage of the manufacturing process. This includes random sampling of the finished product to test for tensile strength, dimensional accuracy, and resistance to corrosion. Advanced laboratory equipment is used to perform these tests, guaranteeing that the nails meet industry standards and customer specifications.

Packaging and Distribution

After passing quality control, concrete nails are packaged for distribution. Factories employ sophisticated packaging systems that ensure protection during transport, allowing the nails to reach customers in peak condition. Packaging is designed to be user-friendly, often including information about the product and instructions for use. The distribution process is equally streamlined, with factories establishing robust logistics networks to reach contractors and retailers efficiently.

Conclusion

The manufacturing of concrete nails requires a combination of skilled craftsmanship and cutting-edge technology. From raw material selection to quality control and distribution, each stage is crucial in ensuring that the final product meets the demands of modern construction. As the construction industry continues to evolve, factories specializing in concrete nail production will play an integral role in supporting infrastructure development globally. With advances in manufacturing technology, we can expect even greater improvements in the efficiency and quality of these essential construction components in the future.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

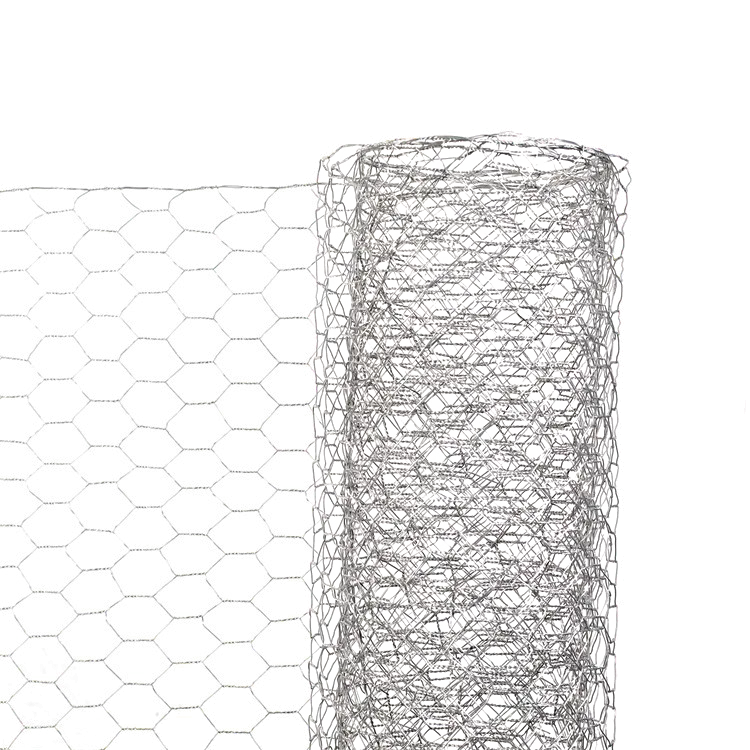

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025