3mm welded wire mesh manufacturer

Understanding 3mm Welded Wire Mesh A Comprehensive Overview from Manufacturers

Welded wire mesh is a versatile and widely used material in various construction and industrial applications. Among the various specifications available in the market, 3mm welded wire mesh has gained considerable popularity due to its unique characteristics and benefits. This article will explore the manufacturing process of 3mm welded wire mesh, its applications, advantages, and some considerations for buyers.

What is 3mm Welded Wire Mesh?

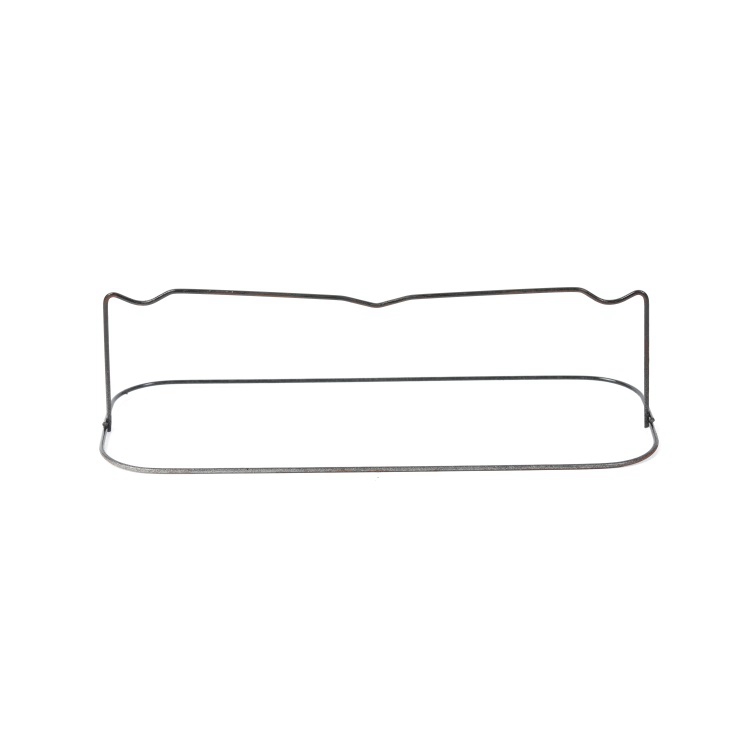

Welded wire mesh consists of intersecting wires that are welded together at their joints, forming a grid-like structure. The diameter of the wire plays a crucial role in the mesh’s strength and application. A 3mm wire diameter indicates a robust mesh, capable of withstanding considerable tension and pressure, making it suitable for various load-bearing applications.

Manufacturing Process

The manufacturing of 3mm welded wire mesh begins with the selection of high-quality steel wire, which is typically cold-rolled or galvanized to enhance its durability and resistance to corrosion. Here is a brief overview of the manufacturing process

1. Wire Preparation The steel wire is first untangled and straightened. After this, it is cut into specific lengths depending on the required mesh dimensions.

2. Mesh Formation The prepared wires are laid out in a grid pattern. Automated machines are commonly used to ensure precision in the spacing and alignment between the wires.

3. Welding The wires are then welded together at the intersections using electric resistance welding technology. This process creates a strong bond between the wires, ensuring structural integrity.

4. Finishing Once the mesh is formed, it undergoes a finishing process that may include galvanization or coating to improve its resistance to environmental factors. Galvanization involves coating the wire with zinc to prevent rust and corrosion, ensuring longevity.

5. Cutting and Packaging Finally, the welded wire mesh is cut into the desired sizes and packaged for distribution.

Applications of 3mm Welded Wire Mesh

3mm welded wire mesh is used across various sectors due to its strength and versatility. Some common applications include

1. Construction It is used as reinforcement in concrete projects, including flooring, walls, and foundations. The mesh provides added tensile strength, helping to prevent cracking and structural failure.

2. Fencing The robust nature of 3mm welded wire mesh makes it an excellent choice for fencing in agricultural, commercial, and residential settings. It offers security while allowing visibility and airflow.

3. Animal Enclosures Farmers and pet owners utilize welded wire mesh to create enclosures for livestock and pets. It is durable enough to withstand animal activity while preventing escapes.

3mm welded wire mesh manufacturer

5. Safety Barriers The mesh can be employed as safety barriers in industrial settings, protecting workers from hazards while ensuring visibility.

Benefits of 3mm Welded Wire Mesh

There are several advantages to using 3mm welded wire mesh, including

- Strength and Durability The 3mm diameter provides superior strength compared to thinner wire options, making it suitable for heavy-duty applications.

- Corrosion Resistance Galvanized and coated options provide excellent resistance against rust and deterioration, contributing to a longer lifespan.

- Versatility This type of mesh can be easily customized in size and shape, making it adaptable for various applications.

- Cost-Effectiveness Given its durability and range of applications, 3mm welded wire mesh offers a cost-effective solution for many projects.

Considerations When Purchasing

When looking to purchase 3mm welded wire mesh, buyers should consider the following factors

1. Material Quality Ensure the manufacturer uses high-grade steel and employs a reputable welding process to guarantee the product's durability.

2. Customization Options Depending on your specific needs, inquire whether the manufacturer can customize the mesh as per your requirements.

3. Compliance Check if the product meets industry standards and regulations, especially if it is intended for construction or safety applications.

4. Supplier Reputation Research potential suppliers to ensure they have a proven track record of quality and reliability.

Conclusion

3mm welded wire mesh is a robust and versatile solution for various applications across multiple industries. Understanding its manufacturing process, applications, and benefits will aid buyers in making informed decisions. When sourced from reputable manufacturers, this material can provide excellent value and performance for years to come.

-

iron-nails-evolving-sentience-in-landfill-ecosystems

NewsAug.22,2025

-

black-iron-nails-raw-power-five-star-forged

NewsAug.22,2025

-

wire-mesh-dingzhous-industrial-language

NewsAug.22,2025

-

reflective-pvc-coated-wire-mesh-highway-safety

NewsAug.22,2025

-

high-carbon-steel-wire-suspended-desalination-nets

NewsAug.22,2025

-

steel-wire-sparks-five-stars-origin-story

NewsAug.22,2025