Durable Electro Welded Wire Mesh for Enhanced Strength and Versatility in Applications

The Advantages of High-Quality Electro Welded Wire Mesh

In various industries and applications, the demand for durable and reliable materials is paramount. Among these, high-quality electro welded wire mesh stands out as an essential component due to its strength, versatility, and cost-effectiveness. This article will explore the advantages of electro welded wire mesh, its applications, and why it is a preferred choice for many projects.

What is Electro Welded Wire Mesh?

Electro welded wire mesh is produced by welding intersecting wires together at their junctions using a combination of electricity and heat. This process creates a robust, uniform structure that offers excellent mechanical properties. The mesh is commonly made from low carbon steel wires, though stainless steel and other materials can also be used for specific applications. The wire diameter, spacing, and mesh size can vary according to requirements, making it a flexible solution for various needs.

Key Advantages of High-Quality Electro Welded Wire Mesh

1. Strength and Durability One of the primary benefits of electro welded wire mesh is its impressive strength and durability. The welding process creates a cohesive bond between the wires, enhancing the overall structural integrity. This makes it ideal for applications where resistance to heavy loads and impact is crucial, such as in construction and infrastructure projects.

2. Versatility Electro welded wire mesh is available in different sizes, shapes, and materials, allowing it to be tailored to meet specific project requirements. Whether used for flooring, fencing, reinforcement in concrete, or as a protective barrier, its adaptability makes it invaluable in various settings, including residential, commercial, and industrial projects.

3. Cost-Effectiveness Compared to alternative materials, electro welded wire mesh is relatively economical. The manufacturing process is efficient, reducing waste and production costs. Additionally, its durability ensures lower maintenance and replacement costs over time, making it a smart investment for long-term projects.

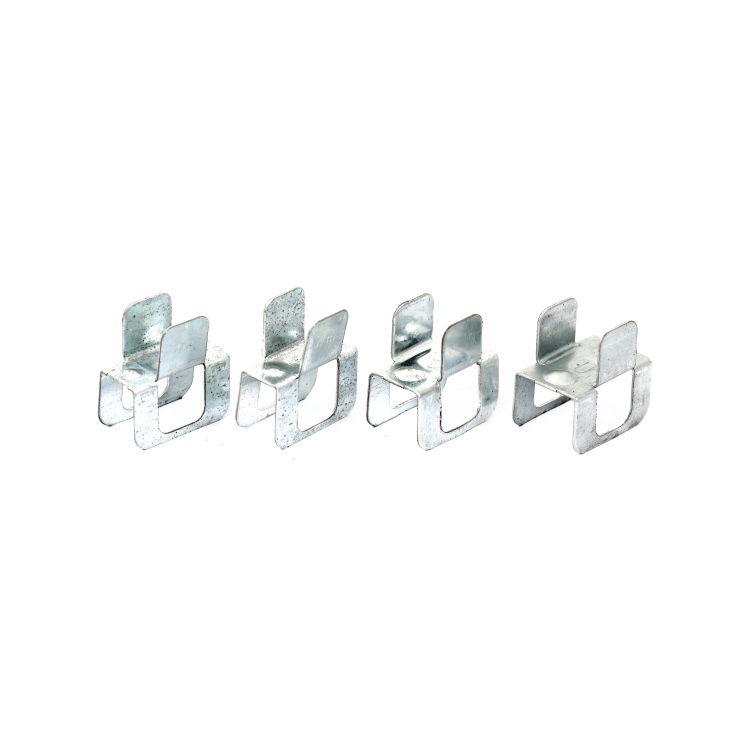

high quality electro welded wire mesh

4. Ease of Installation The uniformity of the mesh facilitates easy handling and installation. Unlike other materials that may require complex cutting or shaping, electro welded wire mesh can be easily rolled out or cut to the desired size and shape. This not only saves time but also reduces labor costs during construction or fencing projects.

5. Corrosion Resistance High-quality electro welded wire mesh can be galvanized or coated with a protective layer to enhance its resistance to corrosion. This is particularly important for outdoor applications or in environments where moisture and chemicals are present. By preventing rust and degradation, the mesh maintains its integrity and extends its lifespan.

6. Aesthetic Appeal While functionality is a primary concern, the aesthetic aspect of materials cannot be overlooked. Electro welded wire mesh can be finished in various ways to suit the aesthetic requirements of the project. Its clean lines and geometric patterns can contribute to modern design elements, making it suitable for architectural applications, as well as landscaping and gardening purposes.

Applications of High-Quality Electro Welded Wire Mesh

Electro welded wire mesh is utilized across a multitude of sectors, including

- Construction Used as reinforcement for concrete slabs, walls, and foundations to enhance structural stability. - Fencing Provides durable, secure barriers for agricultural fields, residential properties, and commercial lots. - Industrial Used in the manufacturing of machinery guards, storage solutions, and shelving systems. - Security Offers protective enclosures for sensitive areas, enhancing safety in various environments. - Landscaping Employed in garden fencing, trellises, and other features that contribute to outdoor aesthetics.

Conclusion

High-quality electro welded wire mesh is a practical and efficient solution, bringing together strength, versatility, and cost-effectiveness. Its wide range of applications, coupled with its superior performance characteristics, make it a top choice for engineers, architects, and contractors alike. As industries continue to seek materials that meet modern safety and efficiency standards, electro welded wire mesh will likely remain a staple in construction and manufacturing. By choosing high-quality products, professionals can ensure that their projects are not only successful but also sustainable in the long run.

-

Iron Nails Evolving Sentience in Landfill Ecosystems

NewsAug.22,2025

-

Black Iron Nails: Raw Power, Five-Star Forged

NewsAug.22,2025

-

Wire Mesh: Dingzhou's Industrial Language

NewsAug.22,2025

-

Reflective PVC Coated Wire Mesh Highway Safety

NewsAug.22,2025

-

High Carbon Steel Wire Suspended Desalination Nets

NewsAug.22,2025

-

Steel Wire Sparks: Five-Star's Origin Story

NewsAug.22,2025