Properties and Applications of Annealed Iron Wire in Various Industries

The Characteristics and Applications of Annealed Iron Wire

Annealed iron wire is a versatile material widely used in various industries due to its unique properties. The process of annealing, which involves heating the iron wire to a specific temperature and then allowing it to cool slowly, significantly changes its microstructure and enhances its overall performance. This article delves into the characteristics, manufacturing processes, and applications of annealed iron wire, showcasing why it is a preferred choice for many applications.

Characteristics of Annealed Iron Wire

1. Enhanced Ductility and Flexibility One of the most prominent characteristics of annealed iron wire is its increased ductility. The annealing process relieves internal stresses, resulting in wire that can be drawn into thinner gauges with significant elongation before breaking. This makes annealed iron wire especially suitable for applications where bending or deformation is necessary.

2. Improved Fatigue Resistance After undergoing the annealing process, the wire exhibits improved fatigue resistance. This means it can withstand repetitive motions and loads without fracturing, making it ideal for dynamic applications such as spring manufacturing or wire ropes.

3. Corrosion Resistance Although iron itself is prone to rusting, annealed iron wire can be coated with various materials to enhance its corrosion resistance. For instance, galvanizing (coating with zinc) creates a protective layer that prevents rusting, making it suitable for outdoor applications.

4. Workability The soft nature of annealed iron wire allows it to be easily manipulated and shaped. This workability makes it a favorite among artisans, builders, and manufacturers who require materials that can be easily formed into specific shapes and designs.

Manufacturing Process

The manufacturing of annealed iron wire involves several steps

1. Wire Drawing The process typically begins with wire drawing, where thicker iron rods are pulled through a series of dies to decrease their diameter and increase their length. The drawing process hardens the wire temporarily, making it less ductile.

annealed iron wire

2. Annealing After drawing, the wire is subjected to an annealing process. It is heated to a temperature that softens the metal, typically between 400°C to 600°C, and held there for a specific period to allow for crystal structure changes. The cooling is done slowly in a controlled environment to prevent the introduction of new stresses.

3. Finishing Once annealed, the wire can be treated with coatings, such as paint or galvanization, to enhance its properties further. Quality control measures are also implemented to ensure that the wire meets designated specifications.

Applications of Annealed Iron Wire

Annealed iron wire has a wide array of applications across different sectors

1. Construction In the construction industry, annealed iron wire is used for reinforcing concrete and in construction mesh, providing tensile strength to structures. Its ductility allows it to be bent and shaped as necessary during construction.

2. Craft and Artisanal Work Many artisans prefer using annealed iron wire for making intricate designs and sculptures. Its flexibility makes it an ideal medium for artistic creations, from jewelry to larger artworks.

3. Agriculture In agriculture, it's commonly used for tying plants to supports, constructing fencing, and creating trellises for climbing plants. The durability of annealed wire withstands outdoor conditions, serving agricultural needs effectively.

4. Manufacturing Annealed iron wire is crucial in manufacturing springs, as its flexibility and fatigue resistance enable it to return to its original shape under repeated stress. Additionally, it is used in the production of various mechanical components and fasteners.

Conclusion

Annealed iron wire is an exceptional material characterized by its ductility, flexibility, and fatigue resistance. The manufacturing process ensures that it meets specific requirements for various applications, making it indispensable in construction, craftwork, agriculture, and manufacturing. As industries continue to evolve, the demand for reliable and versatile materials like annealed iron wire will undoubtedly grow, emphasizing its importance in modern applications. Whether in the hands of a sculptor shaping a work of art or a builder reinforcing a structure, annealed iron wire continues to play a crucial role in numerous fields.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

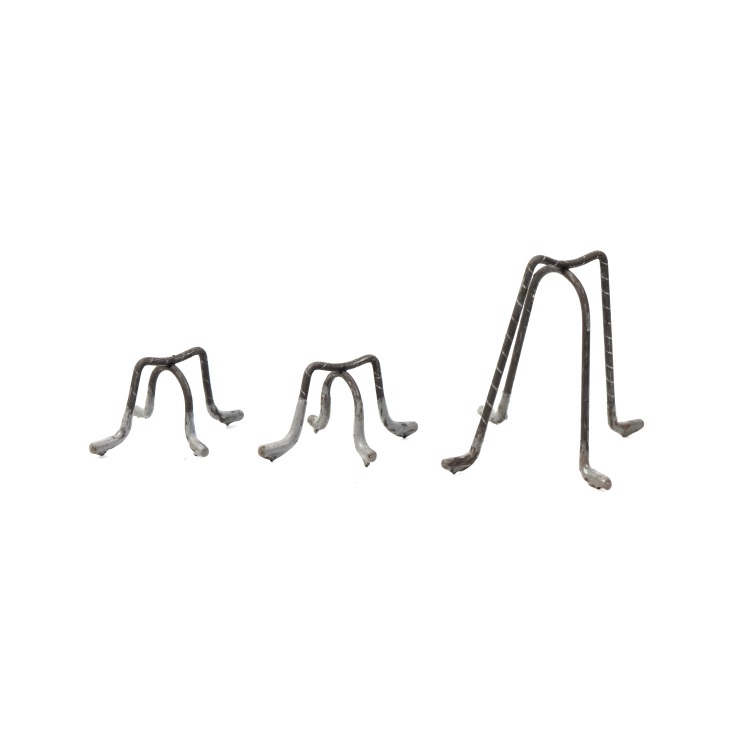

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025