welded wire mesh fence panels in 12 gauge exporters

Welded Wire Mesh Fence Panels in 12 Gauge A Comprehensive Overview of Exporters

Welded wire mesh fence panels have become an essential product for various applications, ranging from agricultural enclosures to industrial fencing and residential boundaries. Among the diverse array of specifications, 12 gauge welded wire mesh is particularly popular due to its balance of strength and flexibility. As the demand for these panels rises globally, understanding the role and offerings of exporters in this sector is crucial.

What is 12 Gauge Welded Wire Mesh Fence Panel?

The term 12 gauge refers to the thickness of the wire used in the mesh. In wire gauge measurements, lower numbers indicate thicker wires; therefore, 12 gauge wire is relatively robust, typically with a diameter of approximately 0.105 inches (or 2.64 mm). The welded wire mesh is constructed by crossing and welding together strands of this wire at regular intervals, creating a grid pattern that provides stability and security.

These panels can be coated in galvanized steel, PVC, or other materials to enhance corrosion resistance, extend their lifespan, and improve aesthetics. The welded construction prevents the mesh from warping and provides a uniform structure, making it an ideal choice for demanding environments.

Applications of 12 Gauge Welded Wire Mesh Fence Panels

The versatility of 12 gauge welded wire mesh fence panels allows them to be used in a variety of settings

1. Agricultural Fencing Farmers utilize these panels to protect livestock, create enclosures, and construct agricultural buildings. Their durability makes them resistant to the elements and wear associated with animals. 2. Industrial Applications In factories and warehouses, welded wire mesh can be used for security fencing, machine guarding, and partitioning, ensuring a safe working environment.

4. Commercial Use Businesses use these panels to create secure perimeters for warehouses, retail spaces, and construction sites, keeping unauthorized individuals out while maintaining visibility.

The Role of Exporters in the Market

welded wire mesh fence panels in 12 gauge exporters

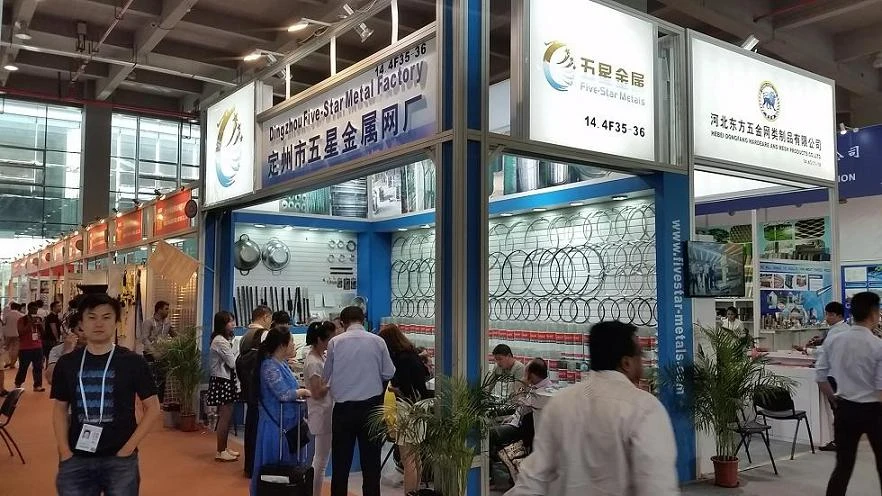

As the global market for welded wire mesh fence panels grows, exporters play a vital role in connecting manufacturers with international buyers. Exporters not only facilitate the distribution of these panels but also serve as a source of information regarding quality standards, compliance regulations, and market trends.

1. Quality Assurance Reputable exporters ensure that the welded wire mesh panels meet international standards such as ASTM or ISO certifications. This not only guarantees product quality but also enhances the reliability of the exported goods.

2. Market Insight Exporters often have in-depth knowledge of different regional markets, allowing them to advise manufacturers on the best approaches to target diverse customer bases. They can also help businesses navigate tariffs, duties, and customs regulations, ensuring smooth transactions.

3. Customization Many exporters provide options for customization, enabling buyers to obtain panels in various sizes, coatings, and configurations that meet their specific requirements. This can be particularly beneficial for niche markets that require unique specifications.

4. Logistics and Supply Chain Management Exporters often handle logistics, ensuring timely delivery of products, which is critical in maintaining customer satisfaction. Effective supply chain management helps in reducing costs and improving efficiency.

Leading Exporters in the Market

The market for welded wire mesh fence panels features several key players known for their high-quality products and extensive networks. Companies based in regions with strong manufacturing capabilities, such as China, the United States, and Europe, are particularly prominent in the global export market.

These exporters often invest in technology and innovation to enhance production processes, further expanding their market reach. They prioritize sustainable practices, such as using recycled materials for wire production and minimizing waste during manufacturing. Such commitments resonate well with today's environmentally conscious consumers.

Conclusion

The demand for 12 gauge welded wire mesh fence panels is on the rise, driven by their versatility and strength. As exporters play a pivotal role in facilitating access to these products across global markets, their commitment to quality, compliance, and customer service becomes increasingly significant. Investing in high-quality welded wire mesh panels not only provides robust security and functionality across numerous applications but also contributes to efficient trade practices in a competitive global landscape. As the market continues to evolve, staying abreast of trends and innovations in welded wire mesh products will be crucial for both consumers and industry players alike.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025