Custom Square Hole Weaving Wire Mesh Filters for Various Applications and Industries

OEM Square Hole Weaving Wire Mesh Filter Net A Comprehensive Overview

In the intricate world of industrial filtration, the choice of materials and designs plays an essential role in ensuring efficiency, longevity, and reliability. One of the standout options in this domain is the OEM square hole weaving wire mesh filter net, which offers a multitude of advantages for various applications. This article delves into the characteristics, benefits, manufacturing process, and potential applications of this innovative filtration solution.

Characteristics of Square Hole Weaving Wire Mesh

The OEM square hole weaving wire mesh filter net is characterized by its square-shaped openings, which provide consistent filtration performance and enhance the flow efficiency of liquids or gases. This mesh is typically crafted from high-quality stainless steel, aluminum, or other alloys, designed to withstand harsh conditions and resist corrosion. The uniformity of the square holes ensures that particles are captured effectively, making it a reliable choice for filtration tasks.

Moreover, the mesh is produced in a variety of wire diameters, which can be tailored to meet specific filtration requirements. The adjustable size of the openings can effectively trap different particle sizes, making it versatile for a range of industries. Whether used in chemical processing, water treatment, or food and beverage production, the square hole weaving wire mesh filter net provides effective solutions for filtering out contaminants.

Advantages of Using OEM Square Hole Weaving Wire Mesh Filter Nets

1. Customizability One of the key advantages of OEM products is the ability to customize specifications according to client needs. Manufacturers can produce square hole weaving wire mesh in various dimensions, wire thicknesses, and materials, ensuring the end product meets precise operational requirements.

2. Durability The materials used in crafting these nets are typically resistant to corrosion and wear, providing longevity even in challenging environments. This durability translates to lower replacement costs and reduced downtime in industrial processes.

3. Efficient Filtration The square hole design allows for optimal flow rates while still maintaining high levels of filtration efficiency. This effectively reduces the risk of clogging and enhances the overall performance of the filtration system.

4. Ease of Maintenance Cleaning and maintaining the square hole weaving wire mesh is straightforward. The design allows for easy backwashing or manual cleaning, ensuring that the filters remain functional over time without substantial labor or operational interruptions.

5. Versatile Applications The versatility of this mesh means it can be utilized across a diverse array of industries. From pharmaceuticals and food processing to mining and petroleum sectors, the applications are vast and varied.

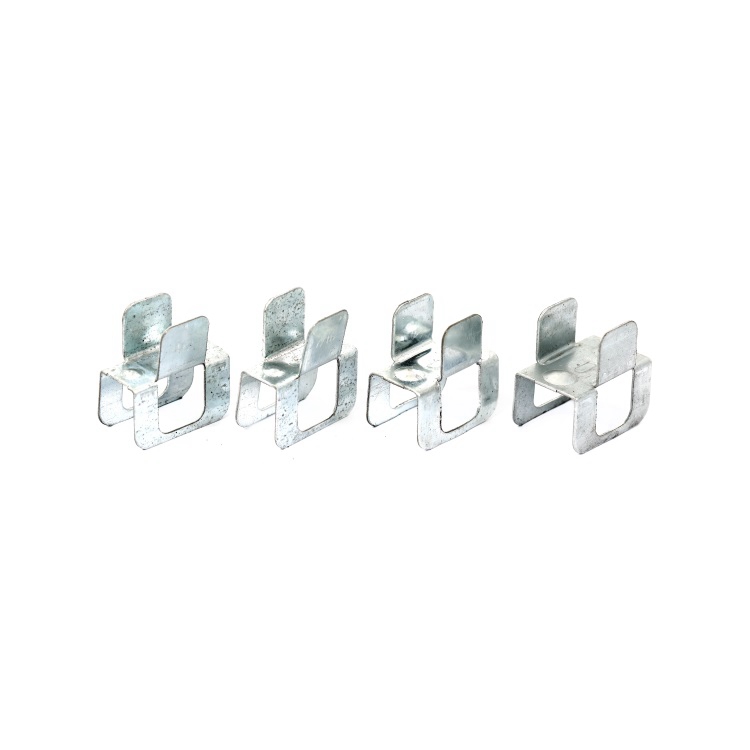

oem square hole weaving wire mesh filter net

Manufacturing Process

The manufacturing of OEM square hole weaving wire mesh involves several critical steps

1. Wire Selection The process begins with selecting high-quality wire materials based on the specific application requirements.

2. Weaving Skilled technicians weave the wires into a mesh using specialized equipment. The weaving technique ensures that the squares are uniform in size, contributing to the filter's effectiveness.

3. Surface Treatment After weaving, the mesh often undergoes treatments such as galvanizing or anodizing to enhance corrosion resistance and overall durability.

4. Cutting and Finishing The final step involves cutting the mesh to the desired sizes and applying any necessary finishing touches to ensure smooth edges and prevent fraying.

Applications

The OEM square hole weaving wire mesh filter net finds applications in various sectors, including but not limited to

- Water Treatment Used to filter particulates from water and wastewater, ensuring cleaner output. - Food and Beverage Industry Essential for maintaining hygiene and safety by filtering contaminants during production processes. - Chemical Processing Designed to handle caustic substances and provide effective filtration. - Mining and Metallurgy Utilized for separation processes and material recovery.

Conclusion

In conclusion, the OEM square hole weaving wire mesh filter net is a significant component of modern filtration systems. Its customizable features, enduring materials, efficient design, and broad applicability make it an optimal choice for industries seeking reliable filtration solutions. As industries continue to evolve, innovations like this mesh will play a pivotal role in enhancing operational efficiency and product quality. Whether you're in manufacturing, processing, or environmental management, investing in quality filtration solutions like the OEM square hole weaving wire mesh is an investment in the future of your operations.

-

iron-nails-evolving-sentience-in-landfill-ecosystems

NewsAug.22,2025

-

black-iron-nails-raw-power-five-star-forged

NewsAug.22,2025

-

wire-mesh-dingzhous-industrial-language

NewsAug.22,2025

-

reflective-pvc-coated-wire-mesh-highway-safety

NewsAug.22,2025

-

high-carbon-steel-wire-suspended-desalination-nets

NewsAug.22,2025

-

steel-wire-sparks-five-stars-origin-story

NewsAug.22,2025