Top Manufacturers of Galvanized Common Round Nails Worldwide

The Rise of Galvanised Common Round Nails Manufacturing Insights

In the world of construction and carpentry, nails are the unsung heroes that hold everything together, quite literally. Among the myriad types of nails available, galvanised common round nails have carved a niche for themselves, thanks to their durability and versatility. As we explore the realm of galvanised common round nails, we delve into their manufacturing processes, the advantages they bring to the table, and the key manufacturers leading this segment.

Understanding Galvanised Common Round Nails

Galvanised nails are coated with a layer of zinc to protect them from corrosion and rust, which makes them particularly suitable for outdoor applications. Common round nails are characterized by their smooth shank and rounded head, making them ideal for a variety of woodwork, including framing, roofing, and general construction tasks. The galvanization process enhances their longevity, ensuring that they can withstand various environmental conditions without losing their structural integrity.

The Manufacturing Process

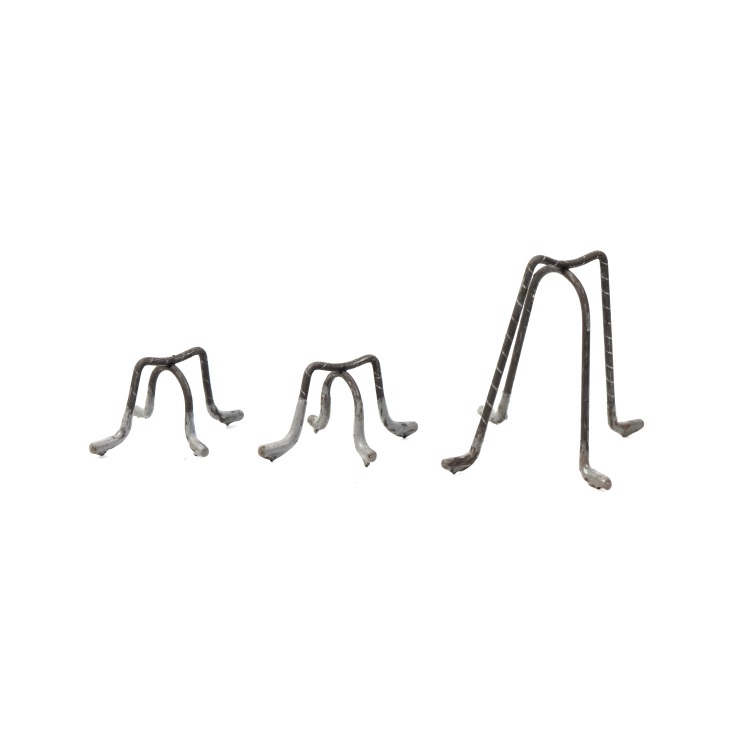

The manufacturing of galvanised common round nails involves several steps, from raw material selection to the final quality assurance checks. The first step is the sourcing of high-quality steel wire, which is usually drawn to the desired diameter for different nail sizes. This wire is then cut into specific lengths, forming the basic body of the nail.

Once cut, the nails undergo a process called wire forming, where they are shaped into the distinctive round form. This is typically achieved through a combination of mechanical or hydraulic forging techniques. After shaping, the nails are heated and passed through a galvanising bath, where they acquire their protective zinc coating. This step is crucial as it ensures maximum corrosion resistance.

After the galvanising process, the nails are cooled and inspected for any defects. Quality control is essential in ensuring that each nail meets industry standards. This often includes tests for tensile strength, bending capacity, and adherence of the galvanising layer. The final step in the manufacturing process is packaging, where nails are sorted by size and bundled for distribution.

Advantages of Galvanised Common Round Nails

galvanised common round nails manufacturers

The popularity of galvanised common round nails can be attributed to several key advantages. Firstly, the galvanisation process makes these nails resistant to corrosion, significantly extending their lifespan. This is particularly important in construction projects exposed to moisture and varying weather conditions.

Secondly, these nails provide excellent holding power due to their design and construction. The smooth shank enables easy driving into different types of wood without splitting, while the rounded head allows for flush application and reduces the risk of surface damage.

Moreover, galvanised nails are environmentally friendly, as they do not leach harmful substances into the ground. Their recycling capabilities contribute to sustainable building practices, making them a choice for eco-conscious builders and contractors.

Key Manufacturers in the Industry

The manufacturing of galvanised common round nails is a competitive field, with several key players dominating the market. Renowned manufacturers have invested in advanced technologies and sustainable practices to enhance their production processes. Companies such as *Grip-Rite, Max,* and *Simpson Strong-Tie* are notable names that have gained recognition for their high-quality products.

These manufacturers emphasize rigorous quality controls and innovation, regularly updating their production lines to meet the evolving demands of the construction industry. They also collaborate closely with contractors and builders to understand their needs, which helps in developing products that are both functional and cost-effective.

Conclusion

Galvanised common round nails are a cornerstone of construction and carpentry, offering durability and reliability for various applications. The meticulous manufacturing process, combined with the advantages of corrosion resistance and holding power, makes these nails an indispensable tool for builders worldwide. As the industry continues to advance, manufacturers are poised to enhance their production methods, ensuring that galvanised common round nails remain a preferred choice in the ever-evolving landscape of construction materials. Whether you are a contractor, carpenter, or DIY enthusiast, understanding the importance of these nails can lead to better project outcomes, ultimately building stronger structures and lasting legacies.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025