tammi . 09, 2025 10:47

Back to list

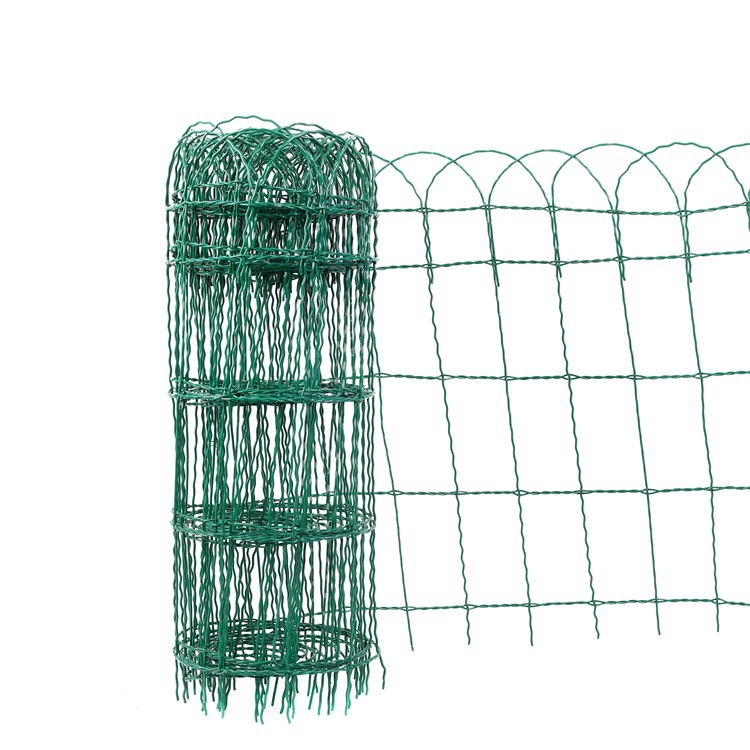

discount steel wire mesh

Steel wire, a versatile material widely utilized across various industries, is an essential commodity in today's industrial landscape. Its inherent strength and durability make it ideal for applications ranging from construction to manufacturing. Understanding the nuances of steel wire varieties, their applications, and the best practices for their use is crucial for industries reliant on this robust material.

Suppliers of steel wire must demonstrate their authoritativeness and credibility, ensuring their products meet international standards such as ASTM or ISO certifications. These standards often dictate the mechanical properties, dimensions, and quality assurance processes, thus playing a pivotal role in the trust that stakeholders place in steel wire products. Further establishing trustworthiness, leading companies offer not just products, but solutions. Through detailed consultations, they provide insights into the most economical and effective wire types for a client's specific applications, ultimately minimizing costs and enhancing performance. Real-World Experiences with Steel Wire Steel wire's reliability and adaptability have been proven in real-world applications time and time again. For instance, in telecommunications, steel wire armored cables protect vital communication lines from physical damage, while offering the flexibility needed for rapid deployment in various terrains. In agriculture, steel wire fencing secures perimeters, ensuring durability against environmental wear and tear. Farmers often express satisfaction with how well such fences withstand animal interactions and severe weather, testifying to their long-term investment value. The continuous innovation in the quality and application processes of steel wire further cements its status as a critical component in modern industry. Experts in steel material sciences drive this innovation, constantly enhancing wire properties to meet increasingly demanding industrial requirements. In summary, the multifunctionality and reliability of steel wire across numerous sectors can't be understated. Knowledge and expertise in selecting and applying the appropriate type of steel wire ensure robust performance, affirming it as a key material in the future of industry advancements.

Suppliers of steel wire must demonstrate their authoritativeness and credibility, ensuring their products meet international standards such as ASTM or ISO certifications. These standards often dictate the mechanical properties, dimensions, and quality assurance processes, thus playing a pivotal role in the trust that stakeholders place in steel wire products. Further establishing trustworthiness, leading companies offer not just products, but solutions. Through detailed consultations, they provide insights into the most economical and effective wire types for a client's specific applications, ultimately minimizing costs and enhancing performance. Real-World Experiences with Steel Wire Steel wire's reliability and adaptability have been proven in real-world applications time and time again. For instance, in telecommunications, steel wire armored cables protect vital communication lines from physical damage, while offering the flexibility needed for rapid deployment in various terrains. In agriculture, steel wire fencing secures perimeters, ensuring durability against environmental wear and tear. Farmers often express satisfaction with how well such fences withstand animal interactions and severe weather, testifying to their long-term investment value. The continuous innovation in the quality and application processes of steel wire further cements its status as a critical component in modern industry. Experts in steel material sciences drive this innovation, constantly enhancing wire properties to meet increasingly demanding industrial requirements. In summary, the multifunctionality and reliability of steel wire across numerous sectors can't be understated. Knowledge and expertise in selecting and applying the appropriate type of steel wire ensure robust performance, affirming it as a key material in the future of industry advancements.

Share

Next:

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025