tammi . 13, 2025 11:52

Back to list

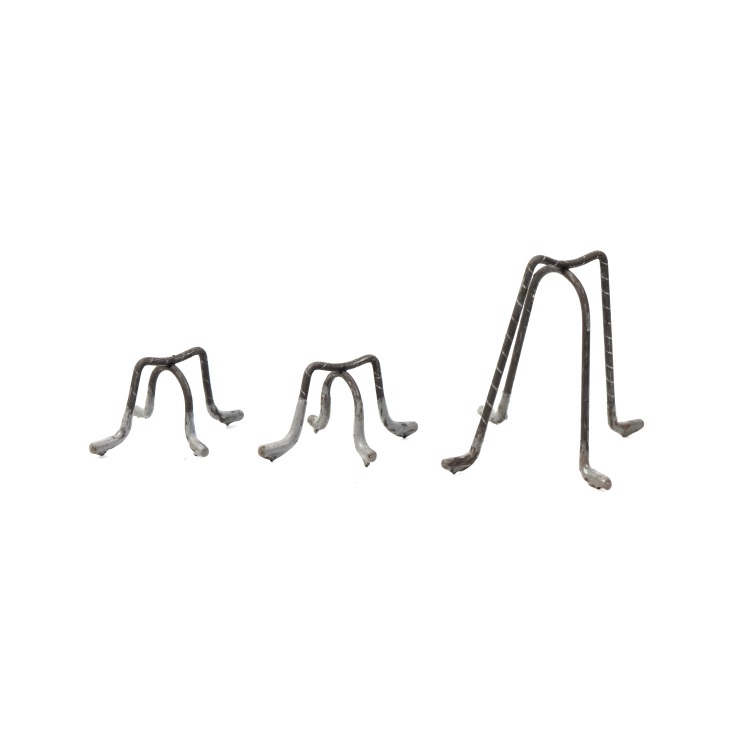

galvanized iron wire unit weight

Understanding the unit weight of galvanized iron wire is essential for professionals in construction, manufacturing, and other industries where this versatile product is utilized. The unit weight can determine material requirements, shipping costs, and efficacy in application. Galvanized iron wire is particularly valued for its resistance to rust and exceptional durability, attributes that stem from its unique manufacturing process.

In application, selecting the ideal unit weight of galvanized iron wire can improve cost-efficiency and environmental sustainability. For lighter applications, where flexibility and easy handling are priorities, like in gardening or DIY projects, opting for a lighter gauge is advantageous. Conversely, for heavy-duty applications such as in high-security fencing or rural infrastructure, a heavier gauge is required. Experts recommend verifying the manufacturer’s specification sheet when sourcing galvanized iron wire, as these provide a reliable reference to the unit weight alongside tensile strength and coating thickness. Top manufacturers follow stringent international standards like ASTM or ISO, ensuring that the wire meets both safety and performance expectations. Industry authorities always emphasize purchasing from authorized distributors to ensure product authenticity, thus fostering trustworthiness and reliable performance. Furthermore, handling galvanized iron wire necessitates expert knowledge, especially in choosing the correct wire for specific environments. Experience shows that in highly corrosive environments, such as coastal areas, thicker zinc layers (achieved through hot-dip galvanizing rather than electro-galvanizing) provide extended durability, justifying the initial investment in higher unit weight wires for long-term savings. Ultimately, those who have comprehensive knowledge about the unit weight and characteristics of galvanized iron wire can better navigate its applications in various scenarios. Continual consultation with technical sheets and liaising with industry professionals ensures adherence to best practices, fostering innovation in uses while maintaining integrity and strength in final applications. This nexus of expertise, authority, and trustworthiness ensures that galvanized iron wire remains a staple in industries relying on its dependable performance and resilience.

In application, selecting the ideal unit weight of galvanized iron wire can improve cost-efficiency and environmental sustainability. For lighter applications, where flexibility and easy handling are priorities, like in gardening or DIY projects, opting for a lighter gauge is advantageous. Conversely, for heavy-duty applications such as in high-security fencing or rural infrastructure, a heavier gauge is required. Experts recommend verifying the manufacturer’s specification sheet when sourcing galvanized iron wire, as these provide a reliable reference to the unit weight alongside tensile strength and coating thickness. Top manufacturers follow stringent international standards like ASTM or ISO, ensuring that the wire meets both safety and performance expectations. Industry authorities always emphasize purchasing from authorized distributors to ensure product authenticity, thus fostering trustworthiness and reliable performance. Furthermore, handling galvanized iron wire necessitates expert knowledge, especially in choosing the correct wire for specific environments. Experience shows that in highly corrosive environments, such as coastal areas, thicker zinc layers (achieved through hot-dip galvanizing rather than electro-galvanizing) provide extended durability, justifying the initial investment in higher unit weight wires for long-term savings. Ultimately, those who have comprehensive knowledge about the unit weight and characteristics of galvanized iron wire can better navigate its applications in various scenarios. Continual consultation with technical sheets and liaising with industry professionals ensures adherence to best practices, fostering innovation in uses while maintaining integrity and strength in final applications. This nexus of expertise, authority, and trustworthiness ensures that galvanized iron wire remains a staple in industries relying on its dependable performance and resilience.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025