galvanized concrete nail factories

The Rise of Galvanized Concrete Nail Factories Innovation Meets Durability

In the realm of construction, the choice of materials plays a crucial role in determining the success and longevity of any project. Among the plethora of fastening options available, galvanized concrete nails have emerged as a preferred choice for many builders. This article explores the rise of galvanized concrete nail factories, their manufacturing processes, and their significance in modern construction.

Understanding Galvanization

Galvanization is a process that involves coating iron or steel with a layer of zinc to prevent corrosion. This protective layer is essential, especially in the construction industry, where materials are constantly exposed to various environmental factors, including moisture, air, and chemicals. By using galvanized concrete nails, builders can ensure that their structures remain sound and durable over time, reducing the need for maintenance and repairs.

The Manufacturing Process

The production of galvanized concrete nails begins with high-quality steel wire, which is drawn into precise diameters based on specific requirements. The wire is then cut into lengths suitable for various uses, typically ranging from 1 inch to 6 inches. After cutting, the nails undergo the galvanization process, which usually involves either hot-dip galvanization or electro-galvanization.

1. Hot-Dip Galvanization In this method, the nails are immersed in molten zinc. The heat of the molten zinc causes it to adhere firmly to the steel surface, creating a thick and robust protective layer. This makes hot-dip galvanized nails ideal for outdoor applications and areas with high humidity.

2. Electro-Galvanization This process involves applying a thin layer of zinc through an electrochemical process. While the protective layer is not as thick as that of hot-dip galvanization, electrogalvanized nails still offer good corrosion resistance and are often used in indoor settings.

After galvanization, the nails are typically tested for quality and adherence of the zinc coating. These quality control measures ensure that the products meet industry standards, providing builders with reliable and durable fastening solutions.

The Demand for Galvanized Nails

galvanized concrete nail factories

With the construction industry witnessing steady growth worldwide, the demand for galvanized concrete nails has surged

. This demand can be attributed to several factors- Durability The long-lasting nature of galvanized nails makes them ideal for various applications, from residential buildings to large-scale infrastructure projects.

- Cost-Effectiveness While galvanized nails may have a slightly higher initial cost compared to non-galvanized options, their durability translates to lower long-term maintenance costs. This cost-effectiveness is a significant selling point for builders and contractors.

- Versatility Galvanized concrete nails can be used in a wide range of materials, including concrete, wood, and masonry. This versatility makes them an essential component in any construction toolkit.

- Environmental Considerations As sustainability becomes a priority in construction practices, builders are increasingly opting for materials that have a lower environmental impact. Galvanization not only extends the lifespan of nails but also reduces waste by minimizing the need for replacements.

The Future of Galvanized Nail Production

As technology continues to evolve, so too will the methods used in galvanizing concrete nails. Innovations such as automated manufacturing processes, advanced quality control techniques, and eco-friendly galvanization methods are likely to shape the future of galvanized nail production. Furthermore, as green building practices gain traction, manufacturers may prioritize sustainable materials and processes to minimize their environmental footprint.

Moreover, the global market for fasteners is expected to grow, driven by urbanization and infrastructure development. Countries in Asia, particularly China and India, are seeing a burgeoning construction sector, leading to a higher demand for quality fasteners, including galvanized concrete nails.

Conclusion

The rise of galvanized concrete nail factories highlights the ever-evolving landscape of the construction industry. By prioritizing durability, efficiency, and environmental considerations, these manufacturers are not only meeting the demands of modern builders but also contributing to the sustainability of construction practices. As we move forward, the role of galvanized concrete nails in shaping resilient infrastructures will undoubtedly become even more significant, reinforcing their status as a cornerstone of construction materials.

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

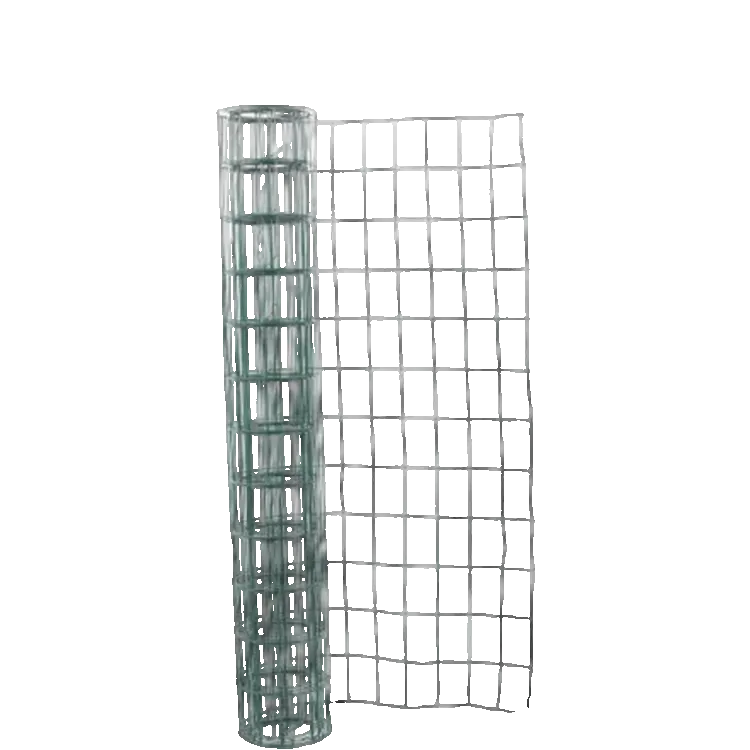

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025