Ene . 21, 2025 05:36

Back to list

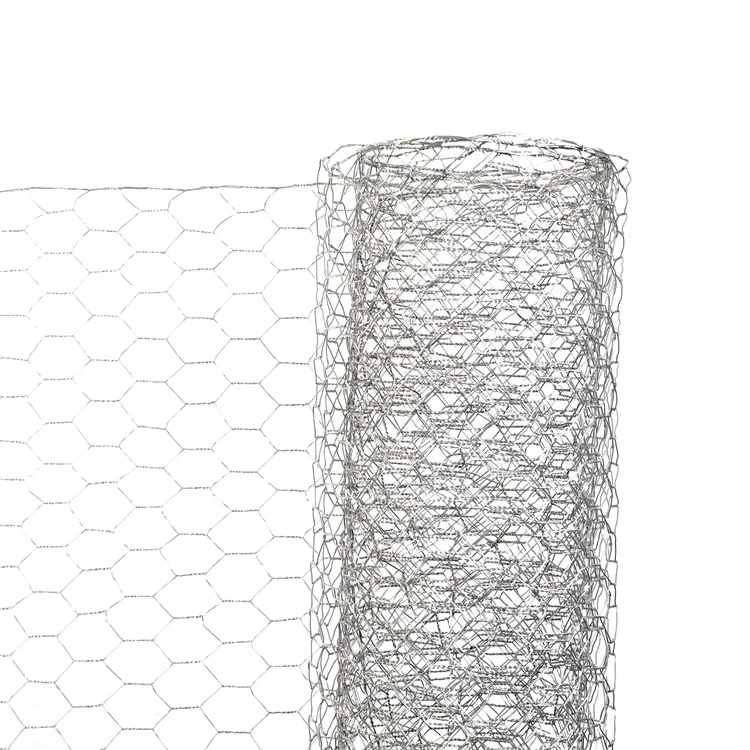

Hot dipped galvanized steel wire

Black annealed wire, commonly referred to as BWG 18 black annealed wire, is an essential product in various industrial applications due to its unique characteristics and versatile nature. This annealed wire is made through a process that involves heating to achieve a softened state, which enhances its flexibility and ductility—key attributes for its widespread use.

From an expert perspective, knowing the precise applications and handling techniques of black annealed wire can enhance efficiency and safety in usage. Professionals in sectors utilizing BWG 18 size wire should be well-versed in selecting the appropriate wire based on tensile strength requirements and the environmental conditions the wire will face. For anyone handling or specifying black annealed wire, understanding its inherent properties and annealing process is vital. This insight ensures the correct selection for the task at hand, optimizing performance and ensuring long-term reliability. Additionally, the supply chain for black annealed wire underscores its importance in global commerce, where quality control and standards adherence are imperative. Working with reputable suppliers who ensure stringent testing and compliance with international norms guarantees that the wire’s performance characteristics are consistently met. As such, knowledge, expertise, and sourcing play pivotal roles in leveraging the benefits of black annealed wire across its varied applications. Professionals in fields that utilize this wire should continually update their knowledge base with the latest advancements and standards to maintain competitiveness and ensure optimized outcomes. In conclusion, BWG 18 black annealed wire exemplifies a key industrial product whose inherent qualities meet the rigorous demands of construction, agriculture, and manufacturing industries. Understanding its processing, usage, and adaptation is essential for anyone engaged in these fields, ensuring that the material offers its maximum potential benefits.

From an expert perspective, knowing the precise applications and handling techniques of black annealed wire can enhance efficiency and safety in usage. Professionals in sectors utilizing BWG 18 size wire should be well-versed in selecting the appropriate wire based on tensile strength requirements and the environmental conditions the wire will face. For anyone handling or specifying black annealed wire, understanding its inherent properties and annealing process is vital. This insight ensures the correct selection for the task at hand, optimizing performance and ensuring long-term reliability. Additionally, the supply chain for black annealed wire underscores its importance in global commerce, where quality control and standards adherence are imperative. Working with reputable suppliers who ensure stringent testing and compliance with international norms guarantees that the wire’s performance characteristics are consistently met. As such, knowledge, expertise, and sourcing play pivotal roles in leveraging the benefits of black annealed wire across its varied applications. Professionals in fields that utilize this wire should continually update their knowledge base with the latest advancements and standards to maintain competitiveness and ensure optimized outcomes. In conclusion, BWG 18 black annealed wire exemplifies a key industrial product whose inherent qualities meet the rigorous demands of construction, agriculture, and manufacturing industries. Understanding its processing, usage, and adaptation is essential for anyone engaged in these fields, ensuring that the material offers its maximum potential benefits.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025