0.8mm GI Tie Wire Production Process and Manufacturing Insights

The Importance of 0.8mm GI Tie Wire in Construction Insights from the Factory

In the realm of construction and manufacturing, the materials used can significantly influence the quality, durability, and overall success of a project. One such essential material is the 0.8mm Galvanized Iron (GI) tie wire. This wire plays a pivotal role, especially in reinforcing structures and ensuring stability. Understanding the manufacturing process and the advantages of using 0.8mm GI tie wire can provide valuable insights into its integral role within various sectors.

What is Galvanized Iron Tie Wire?

Galvanized iron tie wire is a type of wire that has been coated with zinc to prevent corrosion. The 0.8mm specification refers to the diameter of the wire, making it suitable for a variety of applications where strength and flexibility are required. This wire is widely used in the construction industry for tying rebar (reinforcing bars) together, thus providing essential structural support. Its properties make it a preferred choice for contractors and builders looking for reliability and efficiency in their projects.

Manufacturing Process

The production of 0.8mm GI tie wire begins with high-quality iron wire, which undergoes a process of galvanization. The wire is drawn to the desired diameter, ensuring uniform thickness and strength. Following this, the wire is dipped in molten zinc, creating a coating that protects against rust and degradation. This galvanization process is crucial, as it enhances the wire's lifespan, even in challenging environmental conditions.

Factories producing 0.8mm GI tie wire often employ advanced technology and equipment to ensure precision and quality control. This includes automated machinery for wire drawing and galvanization, as well as rigorous testing processes to ensure that the final product meets industry standards. Quality assurance is key in the manufacturing of tie wire, as any flaws could lead to structural failures in construction projects.

Advantages of 0.8mm GI Tie Wire

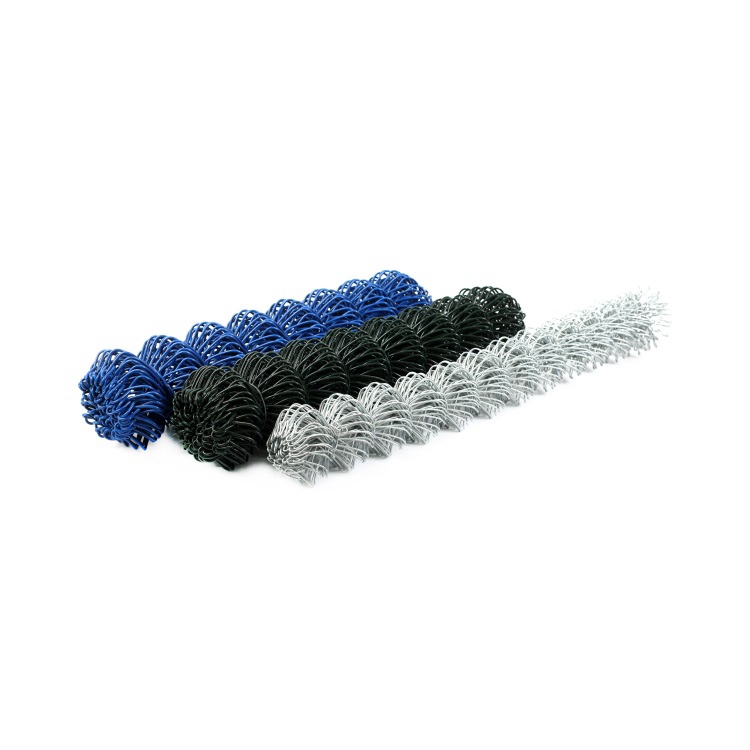

0.8mm gi tie wire factory

1. Corrosion Resistance The galvanized coating of the 0.8mm GI tie wire provides excellent protection against rust and corrosion. This is particularly important in construction applications where the wire may be exposed to moisture and other environmental factors.

2. Strength and Flexibility The wire's diameter offers a balance of strength and flexibility, making it easy to work with during construction. Builders can easily bend and twist the wire to secure rebar effectively without compromising its structural integrity.

3. Cost-Effectiveness Using 0.8mm GI tie wire can be a cost-effective solution for construction projects. Its durability means fewer replacements over time, and its versatility allows it to be used in various applications, from small-scale projects to large infrastructures.

4. Eco-Friendly The process of galvanization not only enhances the durability of the wire but also minimizes the environmental impact compared to other materials that may require more intensive protective measures.

Conclusion

In summary, the 0.8mm GI tie wire represents a crucial component within the construction industry. Its exceptional properties, including corrosion resistance, strength, and flexibility, make it a go-to choice for many builders and contractors. With an efficient manufacturing process, factories dedicated to producing high-quality tie wire ensure that these essential materials meet the demands of modern construction projects.

The significance of 0.8mm GI tie wire cannot be overstated; it is a foundational element that contributes to the durability and safety of structures worldwide. As construction technologies continue to evolve, the reliance on quality materials like 0.8mm GI tie wire will remain imperative for achieving successful outcomes in building and construction endeavors.

-

iron-nails-evolving-sentience-in-landfill-ecosystems

NewsAug.22,2025

-

black-iron-nails-raw-power-five-star-forged

NewsAug.22,2025

-

wire-mesh-dingzhous-industrial-language

NewsAug.22,2025

-

reflective-pvc-coated-wire-mesh-highway-safety

NewsAug.22,2025

-

high-carbon-steel-wire-suspended-desalination-nets

NewsAug.22,2025

-

steel-wire-sparks-five-stars-origin-story

NewsAug.22,2025