يناير . 11, 2025 11:33

Back to list

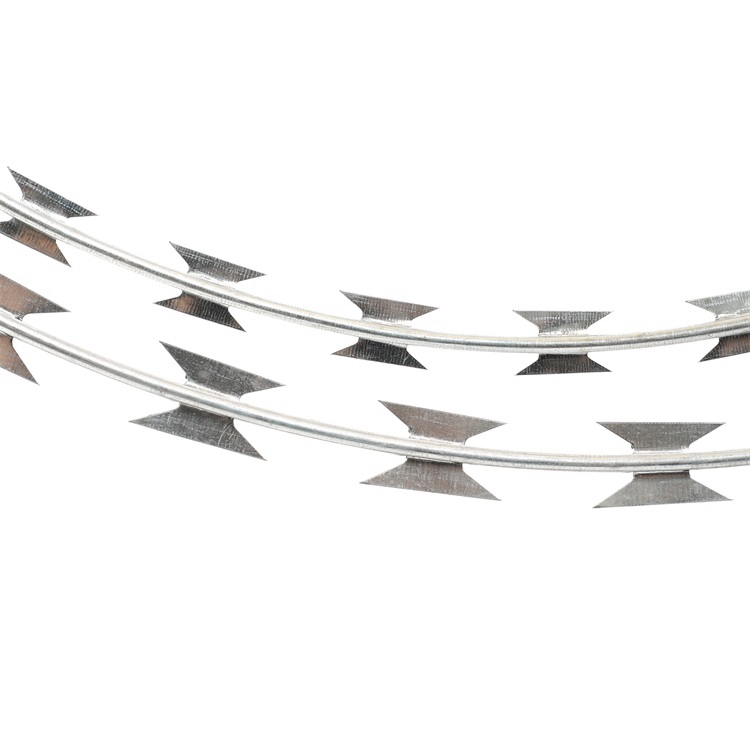

galvanized barbed wire

The manufacturing and industrial sectors have come to increasingly rely on robust materials that offer both durability and versatility. Cold drawn galvanized wire stands out as a pivotal product in these fields, bringing a wealth of benefits drawn from its unique manufacturing process and material properties.

Expertise in the manufacture and application of cold drawn galvanized wire is essential. The modernization of production facilities and the continued research and development efforts have refined the production methods, enabling manufacturers to offer products that meet the ever-increasing demands for precision and strength. Skilled technicians and engineers work collaboratively to ensure every batch meets stringent quality standards, thus reinforcing the wire's position as a trusted component in complex engineering projects. Authoritativeness in the cold drawn galvanized wire market is backed by certifications and compliance with international standards. Leading manufacturers frequently undergo audits to ensure processes adhere to ISO requirements. Adherence to such global benchmarks not only ensures the highest quality of output but also assures customers of the wire's credibility as a top-tier material. The documented performance and proven track record of the wire contribute to its standing as a material of choice in critical applications requiring reliability and robustness. Trustworthiness is fundamentally rooted in the consistent performance of cold drawn galvanized wire across all conditions. Trust is further amplified by the transparency manufacturers provide regarding the production processes and materials used. Detailed datasheets and comprehensive testing results are often shared with clients, ensuring no compromises on quality and reliability. Moreover, client testimonials and case studies add layers of trust through shared success stories, reinforcing the wire’s credibility and easing the decision-making process for prospective users. In conclusion, cold drawn galvanized wire’s unique combination of strength, durability, and resistance to corrosion makes it a superior choice for numerous industrial applications. From agricultural fencing to modern architectural marvels, this wire delivers on all fronts—protection, performance, and cost-efficiency. The continuous advancements in its production and the stringent quality controls employed by leading manufacturers ensure that it remains an authoritative choice globally, trusted by experts and industries alike.

Expertise in the manufacture and application of cold drawn galvanized wire is essential. The modernization of production facilities and the continued research and development efforts have refined the production methods, enabling manufacturers to offer products that meet the ever-increasing demands for precision and strength. Skilled technicians and engineers work collaboratively to ensure every batch meets stringent quality standards, thus reinforcing the wire's position as a trusted component in complex engineering projects. Authoritativeness in the cold drawn galvanized wire market is backed by certifications and compliance with international standards. Leading manufacturers frequently undergo audits to ensure processes adhere to ISO requirements. Adherence to such global benchmarks not only ensures the highest quality of output but also assures customers of the wire's credibility as a top-tier material. The documented performance and proven track record of the wire contribute to its standing as a material of choice in critical applications requiring reliability and robustness. Trustworthiness is fundamentally rooted in the consistent performance of cold drawn galvanized wire across all conditions. Trust is further amplified by the transparency manufacturers provide regarding the production processes and materials used. Detailed datasheets and comprehensive testing results are often shared with clients, ensuring no compromises on quality and reliability. Moreover, client testimonials and case studies add layers of trust through shared success stories, reinforcing the wire’s credibility and easing the decision-making process for prospective users. In conclusion, cold drawn galvanized wire’s unique combination of strength, durability, and resistance to corrosion makes it a superior choice for numerous industrial applications. From agricultural fencing to modern architectural marvels, this wire delivers on all fronts—protection, performance, and cost-efficiency. The continuous advancements in its production and the stringent quality controls employed by leading manufacturers ensure that it remains an authoritative choice globally, trusted by experts and industries alike.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025