يناير . 20, 2025 03:48

Back to list

Galvanized chain link fence mesh roll

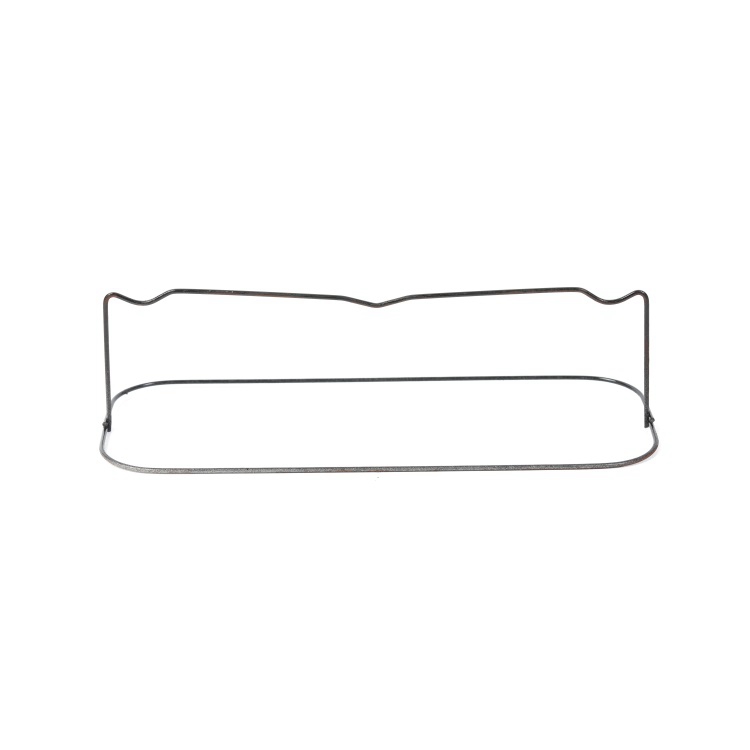

10 gauge black annealed tie wire serves as an essential component for a wide range of industrial and construction applications. Known for its flexibility, durability, and corrosion resistance, this particular type of wire offers several advantages, making it a staple in the toolkits of professionals. Exploring the unique characteristics and applications of 10 gauge black annealed tie wire can enhance the decision-making process for its use.

The expertise required for selecting and implementing black annealed tie wire should not be underestimated. Professionals need to understand the appropriate gauge for specific applications to optimize both functionality and cost-effectiveness. Employing the right tools for cutting and bending, such as pliers designed for heavy-gauge wire, is also crucial to achieve precise applications without compromising the wire's structural properties. From an authoritativeness standpoint, following industry standards and best practices in the application of black annealed tie wire is essential. The American Society for Testing and Materials (ASTM) provides guidelines and specifications that inform optimal usage and safety standards. Compliance with these guidelines not only ensures the safety and reliability of the construction but also enhances trustworthiness in the eyes of stakeholders and regulatory bodies. Consumers and professionals alike are often concerned with the trustworthiness of the materials they use, and black annealed tie wire is no exception. When sourcing this wire, it is vital to confirm that manufacturers provide certificates of compliance that verify adherence to specified quality standards. This verification process assures users that the wire will perform as expected, safeguarding construction integrity and longevity. In summary, the 10 gauge black annealed tie wire stands out for its unique annealing process, offering exceptional flexibility and strength. Its adaptability across multiple domains such as construction and agriculture underscores its value and necessity. Professionals should not only focus on the immediate applications but also rely on industry standards and quality certifications to ensure the wire's long-term reliability and performance. Employing black annealed tie wire with an informed approach enhances not just the structural outcomes but also elevates professional credibility within industries reliant on these materials.

The expertise required for selecting and implementing black annealed tie wire should not be underestimated. Professionals need to understand the appropriate gauge for specific applications to optimize both functionality and cost-effectiveness. Employing the right tools for cutting and bending, such as pliers designed for heavy-gauge wire, is also crucial to achieve precise applications without compromising the wire's structural properties. From an authoritativeness standpoint, following industry standards and best practices in the application of black annealed tie wire is essential. The American Society for Testing and Materials (ASTM) provides guidelines and specifications that inform optimal usage and safety standards. Compliance with these guidelines not only ensures the safety and reliability of the construction but also enhances trustworthiness in the eyes of stakeholders and regulatory bodies. Consumers and professionals alike are often concerned with the trustworthiness of the materials they use, and black annealed tie wire is no exception. When sourcing this wire, it is vital to confirm that manufacturers provide certificates of compliance that verify adherence to specified quality standards. This verification process assures users that the wire will perform as expected, safeguarding construction integrity and longevity. In summary, the 10 gauge black annealed tie wire stands out for its unique annealing process, offering exceptional flexibility and strength. Its adaptability across multiple domains such as construction and agriculture underscores its value and necessity. Professionals should not only focus on the immediate applications but also rely on industry standards and quality certifications to ensure the wire's long-term reliability and performance. Employing black annealed tie wire with an informed approach enhances not just the structural outcomes but also elevates professional credibility within industries reliant on these materials.

Share

Latest news

-

The Ultimate Guide to Premium Quality Field Fence Solutions

NewsAug.12,2025

-

The Essential Guide to Premium Square Wire Mesh Solutions

NewsAug.12,2025

-

The Essential Guide to Hexagonal Wire Netting Farm Fencing

NewsAug.12,2025

-

Premium Continuous Deck Rail Slab Bolster Solutions

NewsAug.12,2025

-

High-Performance Aluminum Tie Wire Reel for Construction Applications

NewsAug.12,2025

-

Crafted Premium Galvanized Hexagonal Gabion Wire Mesh Solutions

NewsAug.12,2025